If you run a professional workshop, the right woodwork design software has the power to transform your business.

We review the best options to take you from design to build. After all, what’s the point of a design package that won’t provide you with the information to manufacture your project?

For all hobbyists reading, some of the packages we review are accessible at an entry-level so please read on!

Information overload

Google woodworking design software.

…and you’ll find a ton of products that turn out to be project management tools, financial and ordering packages, and offer little to no design capability.

…or they don’t focus on woodwork at all; although cool, enough of the CAD packages showcasing jet engines and motorbikes!

Google free woodworking design software.

…and the products and comparison websites that pop up list products that don’t end up being free at all.

We’ll filter all this out, but before going any further, tackle this question…

Can I get what I need for free?

Well, really the answer is no, for any decent woodwork software anyway.

You may find some paid solutions that offer a limited set of free features to entice you in, but they won’t allow you to get all the way from design to production.

How we’ll assess each software

To be of any use it must do these 2 things:

1. Offer a visual representation of your project

This might be in 2D or 3D or both and is required to:

Visualise and assess your design as you work on it

See if it fits the space

Check on aesthetics

Show your customer to agree changes and close the order

2. Provide information to allow you to build your project

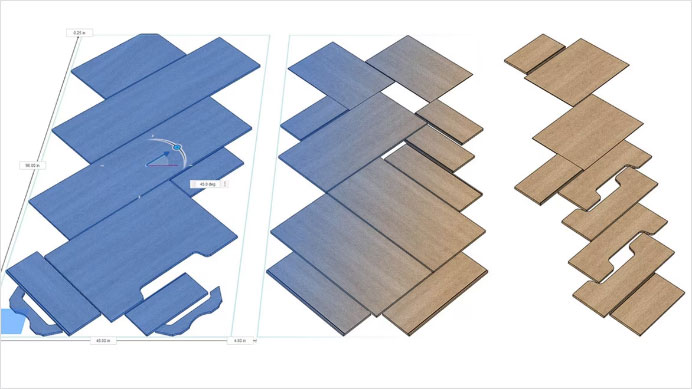

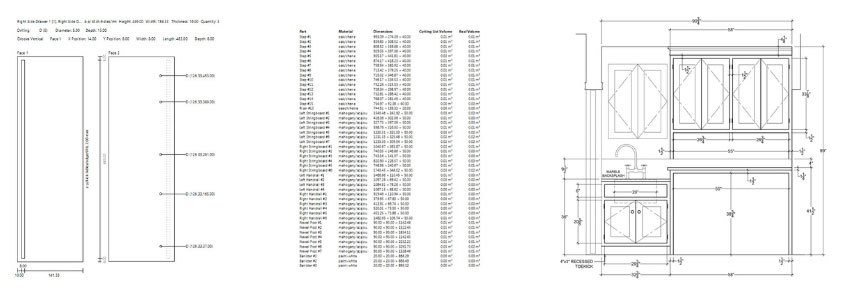

By that we mean output accurate files and drawings that allow you to cut and assemble your design, specifically:

- A cutting list of parts including dimensions and materials

- 2D plans of each part

- Dimensioned whole project drawings to aid assembly

- Details of hardware positioning and for CNCs the machining details

- CNC files of each part to run your machine, and these should include toolpath data to enable automatic application of those toolpaths by the CNC

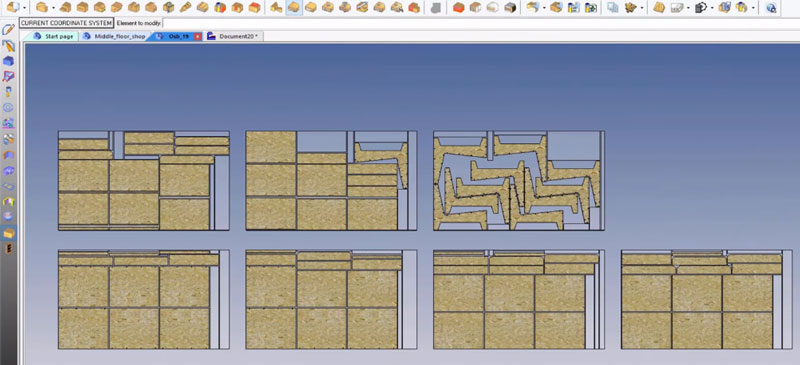

- Extra production features e.g. cutting or nesting optimisation of parts

- Project costs to quote accurately (not essential but nice to have)

There are an awful lot of Computer Aided Designer (CAD) packages that can be used to design pretty much anything, and that can create wonderful 3D renders and plans.

Many of them say they’re good for woodwork and provide the pictures to prove it.

However…most don’t easily produce the manufacturing output you need.

Other key points to consider

Drawing based vs parametric design methodology

With a typical CAD package you will draw project components on screen. It is a relatively slow process to draw all components in turn and make edits, again to each part in turn.

Parametric design of a cabinet on the other hand would typically start with a cabinet carcass, then components like shelves and drawers are added, positioned and various other parameters are configured.

The choice comes with a trade-off.

Drawing based

- ‘Draw’ practically anything you can imagine

- Slow and error prone as individual components are individually designed

- Editing a design is also slow and inaccurate

- Typically hard or impossible to quickly access accurate manufacturing output

Parametric

- Limitation to the scope of the design, typically the focus therefore is cabinetry rather than for example free form solid wood chairs and tables

- Potential to be 100% accurate

- Fast to edit a project, resize a cabinet and all internal parts resize automatically

- Fast access to reliable manufacturing output

All solutions fall into one of these two categories.

Can I realistically master the software?

- Complexity of use

- Ease of learning

- Support and resources

All pro design software for woodworking will come with a learning curve.

However, it’s important the software isn’t too hard to learn, or the design process too slow. The size and skills of your design team need to be factored in here too.

Price point

A good software that isn’t too hard to use will pay for itself many times over, but it may simply be unaffordable depending on your budget. We comment on:

- The likely budget required, although the more expensive the package, the harder it can be to identify exact pricing

- Whether you can access a free or trial version and whether that’s limited in terms of time or features

- Subscription or single purchase details

- Consideration for maintenance fees, add-ons and additional modules

Software we are not reviewing but some ideas anyway!

- Joinery software for doors and windows, although we do hear a lot of good things about Joinerysoft

- Construction software for houses, sheds, conservatories and other timber frame projects

- Photorealistic rendering software; no true woodwork design software offers photorealistic rendering, but you will often be able to export designs to a photo rendering package or add-on; one of our favourite packages is KeyShot

- Stair software, a specialist niche within woodwork, we offer StairDesigner

- Interior design software, typically for planning and displaying room layouts

A special mention for CAM software

Important but not a design solution!!

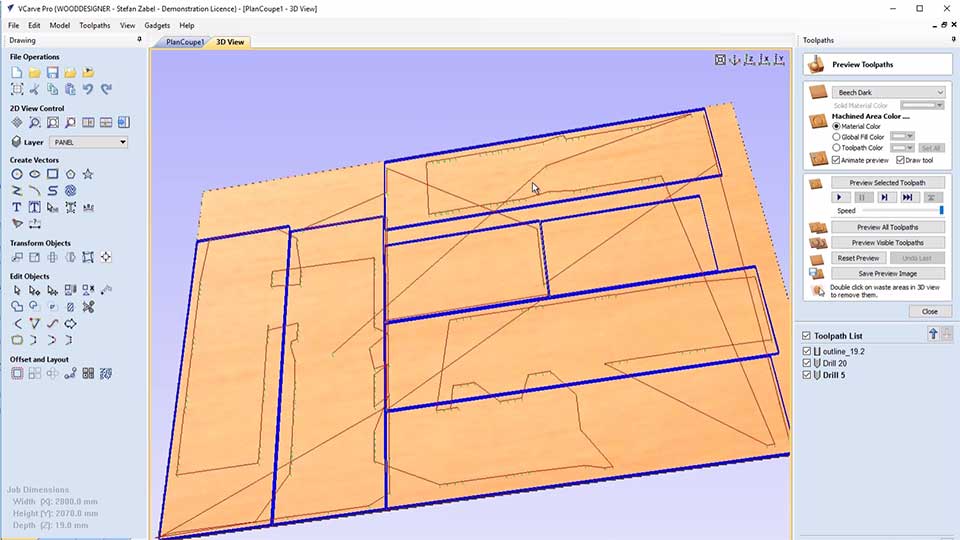

If you have a CNC machine, you will need Computer Aided Manufacturing (CAM) software to run it. Specifically, it applies the toolpaths to cut and machine the parts and generates the actual machine code to operate the CNC.

Often you can manually take a cutting list and input part sizes directly into the CAM software, and again manually apply toolpaths. You can work like this but it is very slow and error prone.

To ensure CNC production is fast and efficient and you see a good return on your investment, it is important to add a design software that automatically sends the output files (details on how to cut each part) to the CAM software.

And secondly, that this design software includes enough data in that output to allow the CAM software to automatically apply the toolpaths.

Our list of the best software for woodwork design

SketchUp

Drawing flexibility vs parametric efficiency

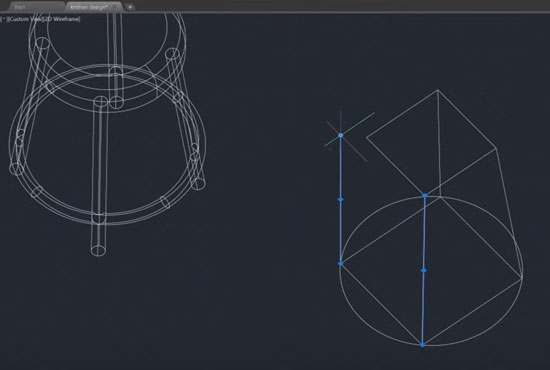

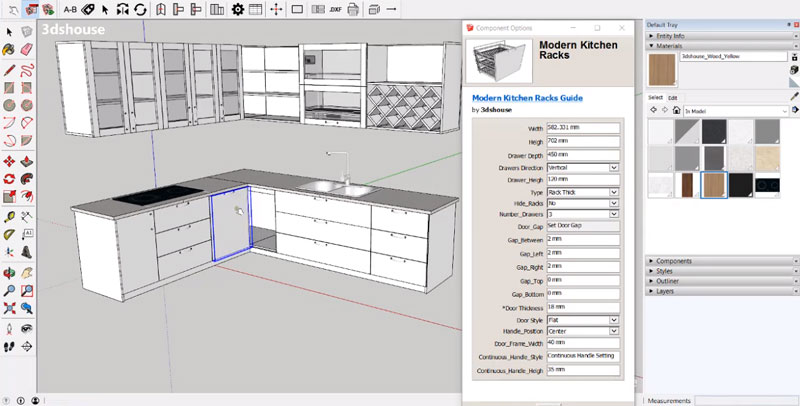

SketchUp is a popular CAD based design tool, although it’s not a traditional complete CAD software in the same sense as programmes like AutoCAD.

It can absolutely be used by woodworkers, and it’s relatively simple to get nice 3D images. As it’s CAD, while it may lack some of the advanced features found in dedicated CAD software you have huge scope to create pretty much anything you want.

However, each part needs to be drawn, which takes a long time, so it’s not an efficient process for a busy workshop. If the design needs resizing, each part needs to be resized in turn again, a very error-prone process.

3rd party paid plugins are available to add parametric functions. Cabinetsense is one, but this only works for square and rectangular cabinets, nothing irregular.

Bear in mind that any 3rd party plugins need to be regularly updated to keep pace with SketchUp updates to ensure compatibility.

Renders

It’s relatively simple to get nice 3D images.

3rd party paid plugins can also be used to generate photorealistic renders.

Output

SketchUp is all about creating great designs and seeing them in 3D. However, it isn’t set up to do manufacturing output.

It’s impossible to get output dimensions with the standard version, you’ll need to look at another add-on to do this.

There’s no quick way to get technical assembly plans (including hardware and machining). That said, extensions have again been created to help. Cabinetsense that we mentioned above will produce a cutting list and some DXF output that can be input to CAM software to drive a CNC.

Budget

Very affordable, but paid extensions hike the price. Subscription based with low to medium upfront cost.

Ease of use and support

Mastering the basics is relatively simple, it’s no surprise lots of amateurs use SketchUp too. However, it becomes very tedious for pros working on multiple projects to design and edit all the parts of a cabinet, along with hardware and the walls, doors etc of a room layout.

A lot of training is available via SketchUp Campus, 3rd party extensions will have their own support arrangements.

Free option?

Yes, it comes as a free online woodworking design software, in the form of SketchUp Free. So it’s web based rather than the paid desktop versions. The free option allows you to draw your designs, appraise and edit them, place them within a complex environment, and also to present them to a customer.

However, it doesn’t include the module to output 2D plans, or the ability to combine with extensions which are required to extract cutting lists and CNC output as discussed above.

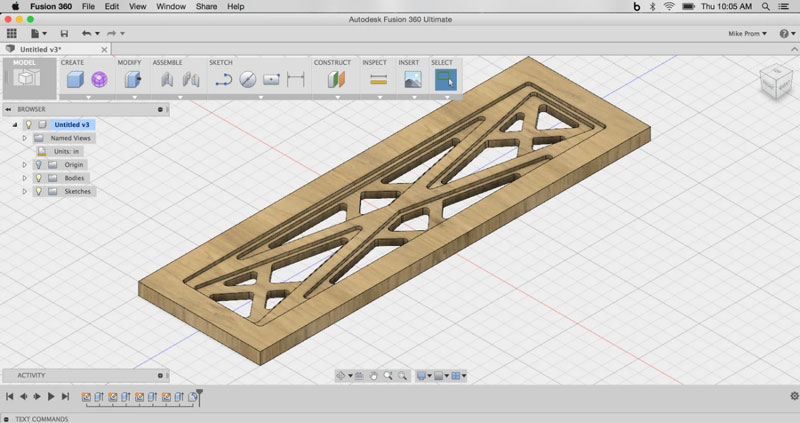

Fusion 360

Created by Autodesk, who also offers Inventor, their flagship engineering design tool.

Drawing flexibility vs parametric efficiency

Although suitable for woodworking, this is not the main focus of the software as we’ll see when we come to the manufacturing output. It is marketed more as an entry level engineering package.

Design is CAD based and consequently can be adapted to a huge range of applications, for example non cabinet / panel based woodwork projects.

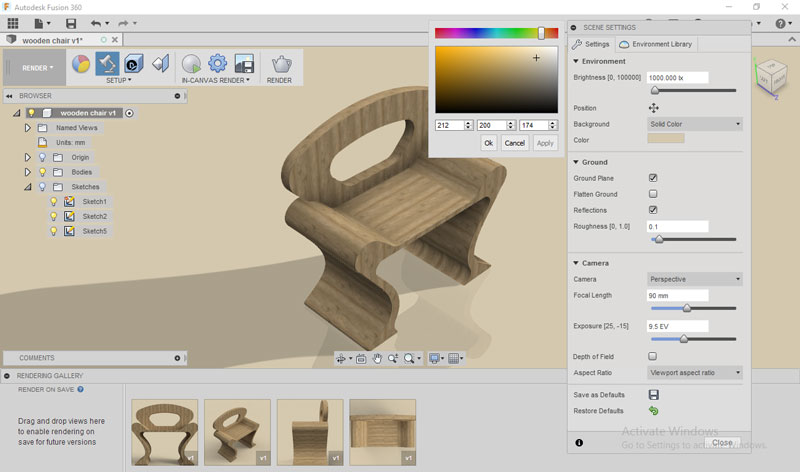

Renders

Access the integrated render workspace to output beautiful photorealistic images of your project. A big plus in Fusion 360.

Output

Woodworking isn’t the focus, which is why you will need a 3rd party add-on to produce the cutting list, like OpenBOM or MapBoards. These can be a bit hit and miss, especially if they aren’t updated quickly when Fusion updates.

A manufacturing extension does however offer some excellent CNC integrations along with a nesting tool.

Budget

Subscription based so it offers a relatively low entry point to using the software. Factor in the ongoing price for the essential manufacturing extension if you use CNCs.

Ease of use and support

Takes some time to master, but there is a large community with lots of easily accessible resources to learn yourself, or utilise a network of certified trainers.

Free option?

Fusion 360 comes as a woodworking design software free download, time limited to 30 days.

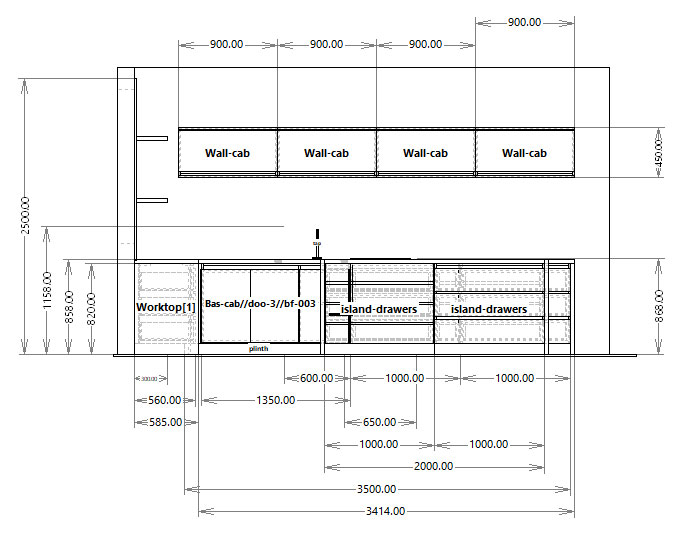

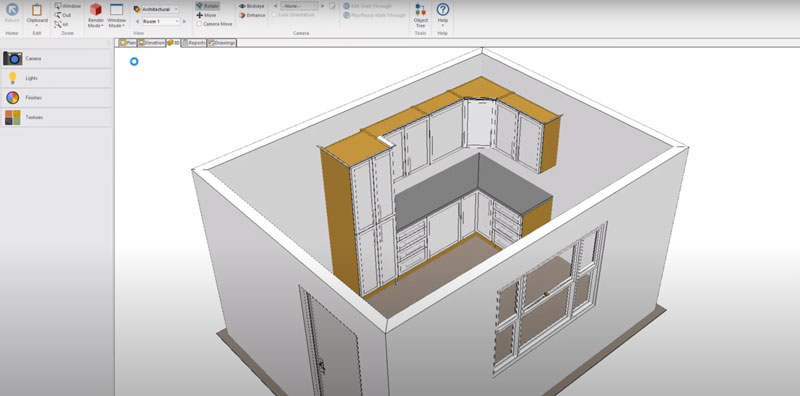

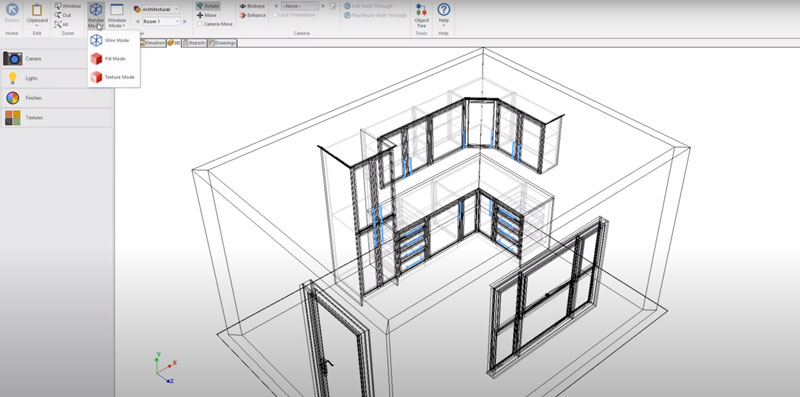

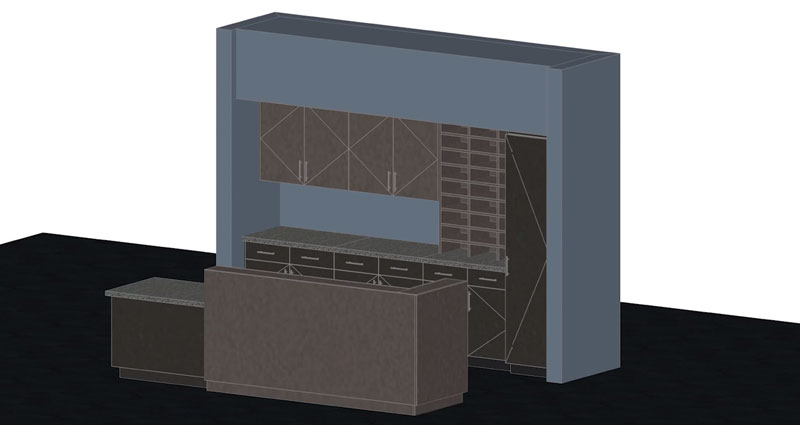

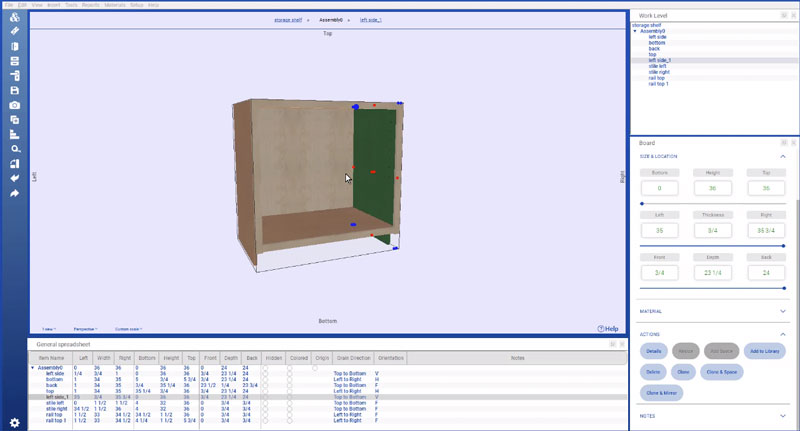

PolyBoard

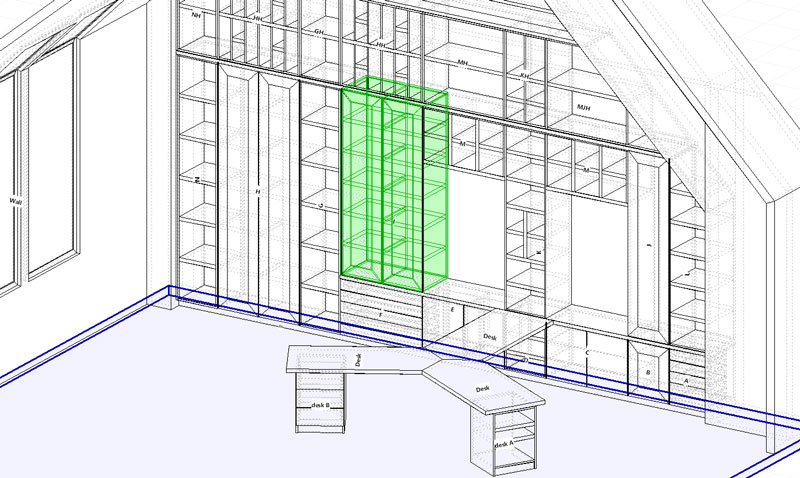

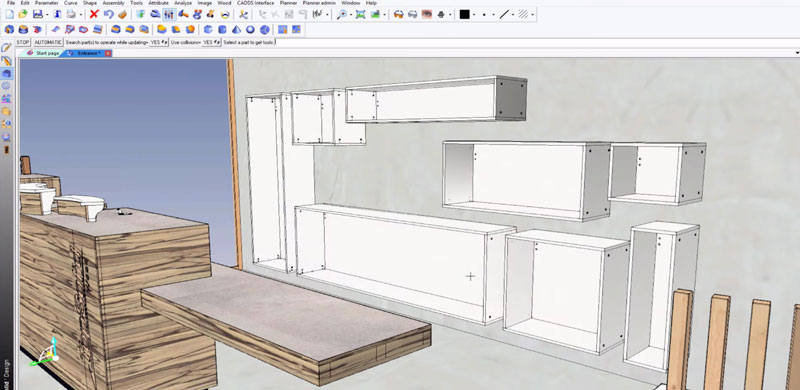

Drawing flexibility vs parametric efficiency

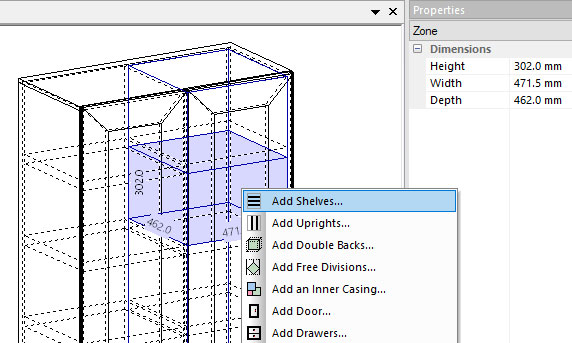

PolyBoard is parametric, not a CAD drawing software, and so is suitable for panel and bar based production of fitted furniture, cabinetry, wardrobes, kitchens and bedrooms.

You start with a cabinet carcass and drop in the shelves, doors, drawers, plinth etc. These aren’t drawn, instead re-position, change material, edging and hardware using a series of parameters.

To really benefit from the power of the software, set up all construction preferences including your favourite hardware within stylesheets and apply in one click to your design.

Because the models are parametric, resize the carcass and all components resize, and hardware is adjusted and repositioned automatically.

PolyBoard also manages the calculations of complex geometries. Quickly add sloping tops and sides, and irregular angles, and all components and the output update immediately. This is a very fast and accurate way to design.

Renders

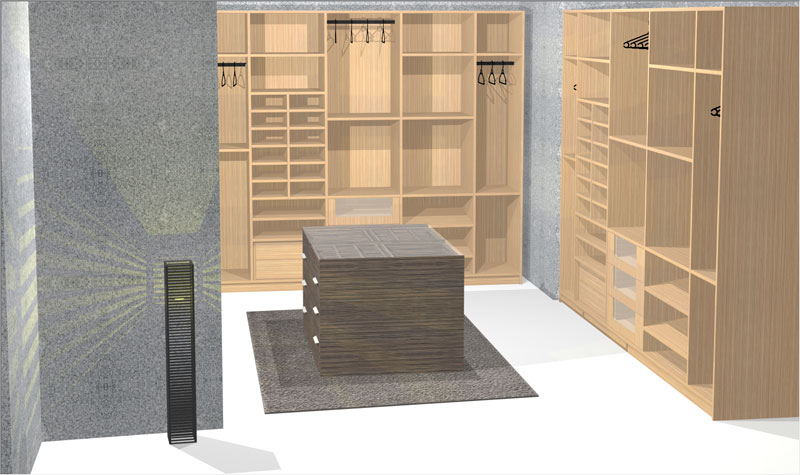

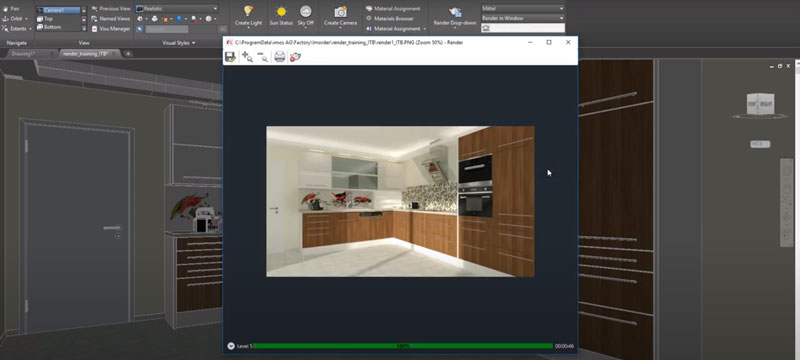

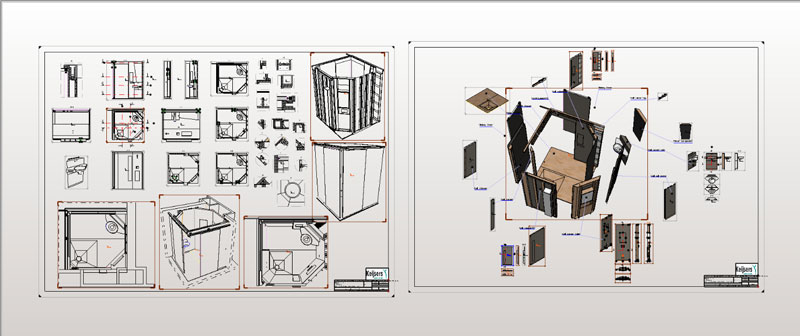

3D rendering can be achieved within PolyBoard (see below), including application of any material, plus 3D accessories like chairs and interior decor:

The software outputs 3DS and 3D DXF files to allow integration with state of the art photorealistic rendering software like 3DS Max, pCon.planner or KeyShot as shown below:

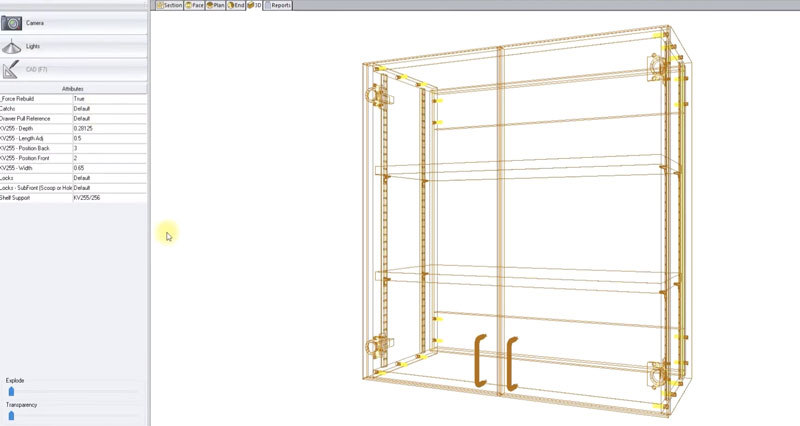

Output

PolyBoard was created as a design to manufacturing solution. Manufacturing output is very much the focus, including instant access to:

- Cut lists

- 2D plans of each part

- Cost and material report

- Layered 2D DXF files to run virtually any CNC

- Native CNC file output for major brands like Homag, Biesse, SCM/Morbidelli, Felder, Vitap and NC-HOPS

- 3D DXF and 3DS output to rendering software

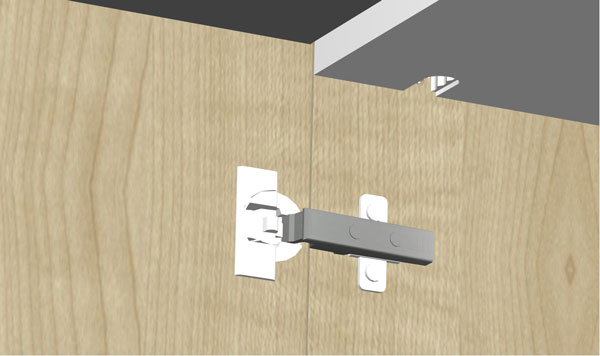

A special mention for hardware management…

The plans include hardware specifications and positioning. If you work with a CNC, all the hardware machining is automatically added and sent to your machine. Tailored output can be split across different CNCs too.

Budget

Mid range software, versions available with and without CNC integration. All prices are shown on the website.

As your business grows, options to add seamless integration of nesting and cutting optimization solutions, OptiNest and OptiCut, or other 3rd party packages.

Ease of use and support

Easy to learn for pro software. Setting up the stylesheets takes a bit of time, but the out of the box configurations can be easily modified. Once that’s done, creating new designs or modifying projects from a model library is simple and extremely fast.

Affordable training and software set up and CNC integration support also available, plus extensive free to view resources and a technical support forum.

Free option?

A free version includes all design features for testing purposes. Any project you work on will be available when you activate the full version.

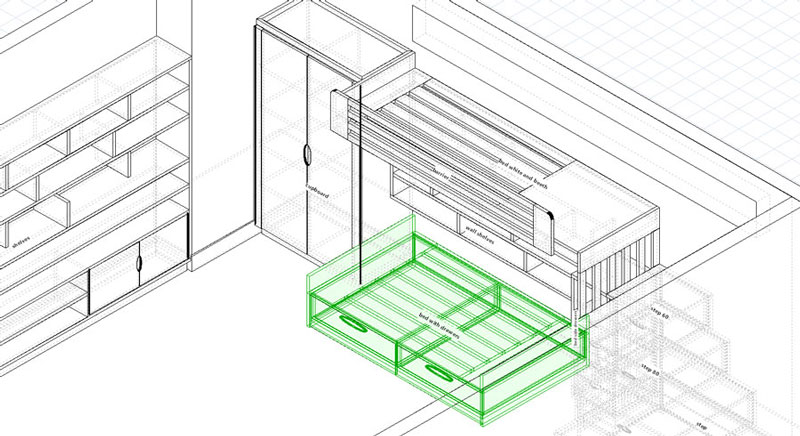

Cabinet Vision

Drawing flexibility vs parametric efficiency

Cabinet Vision is a parametric software like PolyBoard and as the name suggests its sole focus is cabinetry.

You edit object properties rather than draw. You can however apply pre-drawn shapes to create unusual cabinets, add cut outs and other design features. Once your models are set up, editing the overall size is quick and all parts should update accurately with immediate access to the manufacturing output.

It is a powerful modular solution offering a number of add-on packages (some are essentially other software) that integrate well to build up a complete production workflow.

Renders

Basic modules offer good rendering capabilities.

xRendering is another software/module that can be added to the production suite. This offers good photorealistic type rendering.

Output

The core module includes the cut list output, then add separate modules for cabinets and closets to access that functionality.

Additional modules are required for cutting optimizations for panel saws (xOptimizer), and for CNC output (xMachining) for example.

Machining for hardware is comprehensively managed, something you would expect with a good parametric software.

Budget

This comes in very much at the top end of the range as you add in your required modules. Consider the obligatory ongoing maintenance fees as well as the upfront costs.

Ease of use and support

Whilst powerful, there is a steep learning curve. Modifying your designs and configuration can be quite involved, especially across version updates. Suitable for workshops with a dedicated technical design and production team.

Good resources and access to paid training and a technical esupport team.

Free option?

No free option but software demonstrations available with a member of the sales team. Sign up on a subscription basis to try it out.

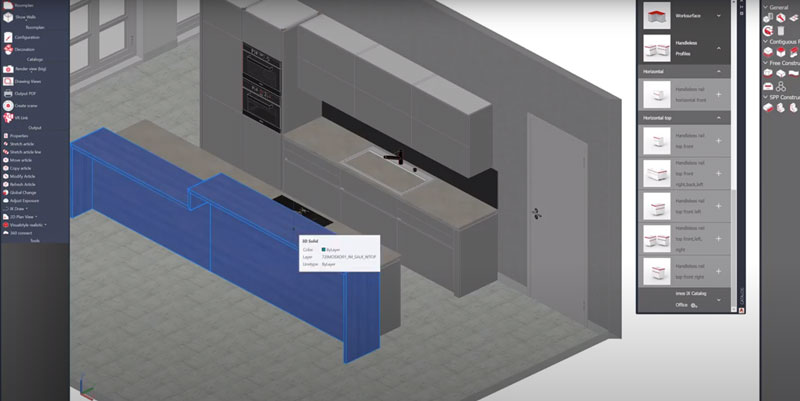

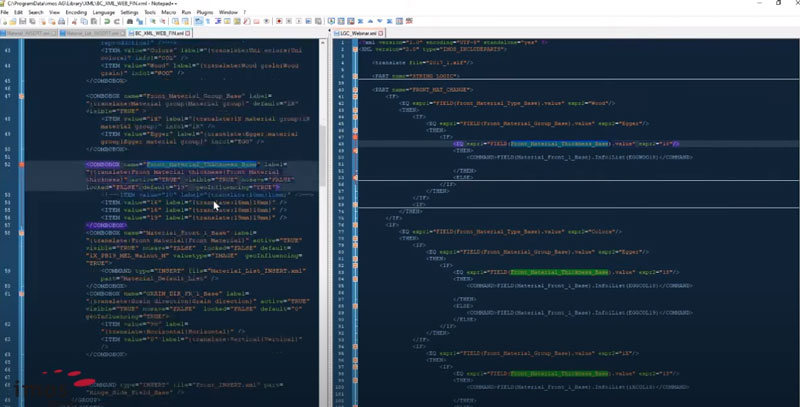

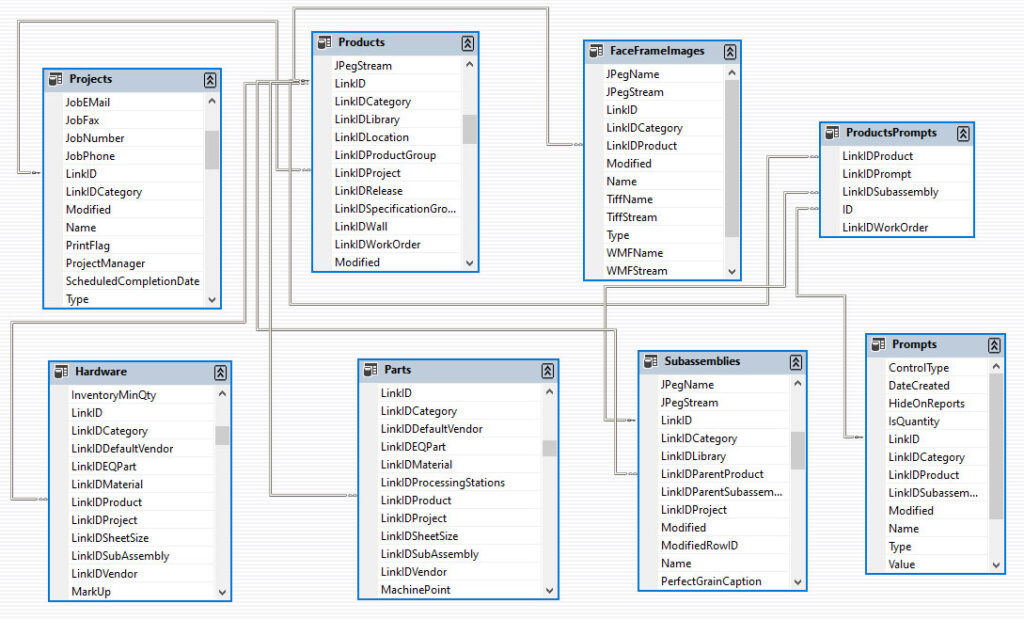

IMOS

Drawing flexibility vs parametric efficiency

IMOS runs on the Autodesk design engine. It adds parametric capabilities with a vast array of design options, both part specific and globally across entire projects. Its main focus is cabinetry, both panel based and solid wood.

It’s nice that you can still access traditional CAD tools which adds more flexibility, although they do open up more human error into the design workflow.

There is a significant set up stage to get your standard models configured correctly, then it is relatively easy to edit their dimensions and other features.

A decent understanding of how to interpret and edit XML coding language, and manage databases, is a key requirement if you want to create custom projects without requiring support from IMOS.

If you are able to allocate a dedicated team to design within your workshop, this software is a very powerful tool.

Renders

3D renders are completed via the Autodesk rendering engine. The software produces good quasi-photo rendering, true photorealistic rendering requires export to 3rd party software.

Output

- Cutting lists, hardware lists, dimensioned plans all included in the manufacturing module

- No cutting and nesting optimization, but good compatibility with 3rd party solutions

- CNC output to popular machine models e.g. Biesse and Homag, but the range is limited so confirm integration early on

Budget

High end, modular software with a large range of features available as paid add-ons. Maintenance contract required to integrate with the latest hardware.

Ease of use and support

Powerful but complex package, requires good knowledge of XML and databases to master. Expect an intensive set up period with ongoing support from IMOS essential.

Lots of resources available, some require a live maintenance contract like online classes.

Free option?

A trial version is not accessible initially. Contact the sales team to register on the IMOS portal to find out more.

Bonus features

Add-ons include some great sales tools, for example running an online store of standard products with customisation options. As usual with a woodworking software design tool for pros, it’s possible to export data to your ERP system.

Some good partner integrations are available including virtual reality walk through software.

TopSolid

Drawing flexibility vs parametric efficiency

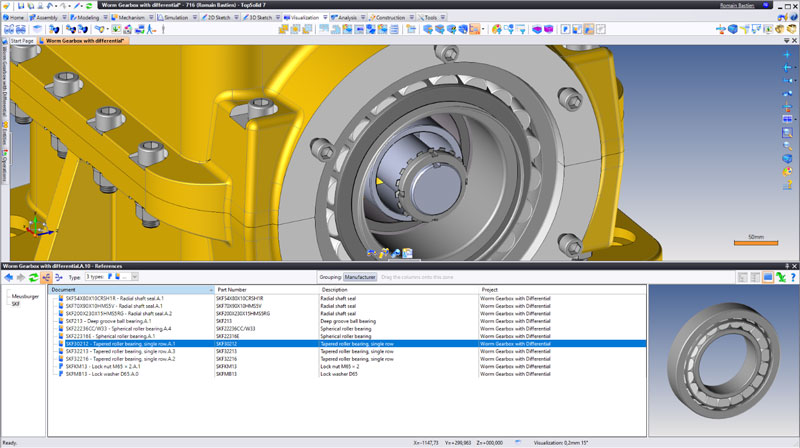

This advanced CAD based drawing software comes with huge flexibility in what you can create. Just take a quick look on their website and you’ll see a range of advanced engineering projects created in the software.

However, you need to manually set up each component separately which is very time consuming and prone to error. This workflow makes sense for custom engineering work, but not necessarily for woodwork.

TopSolid have released TopSolid’Wood to mitigate some of these issues. This includes hardware component libraries complete with machining details.

Renders

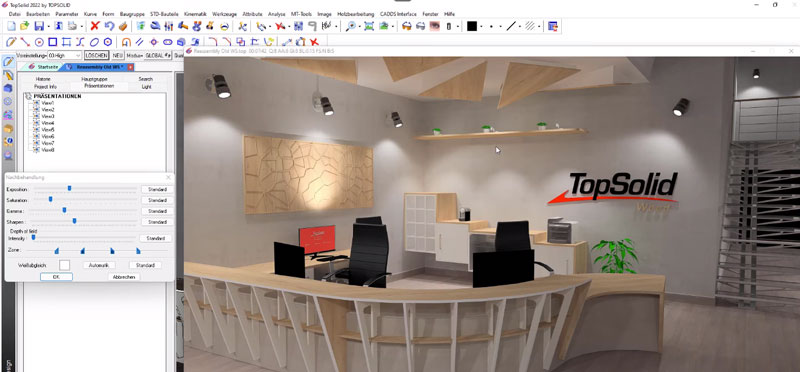

The standard renders are very usable as shown below:

A photorealistic rendering option is built in too:

Output

TopSolid’Wood will allow you quick access to cutting lists, and drawings are high quality.

An additional module called TopSolid’WoodCam offers good output for 4 and 5 axis CNC machining. Nesting and other production options can be incorporated too.

Budget

Very much high end pricing once add-ons, training and maintenance are accounted for. Example businesses TopSolid would suit are production of exhibition stands or commercial spaces, where each project is different and requires a lot of curved and irregular shaped components.

Ease of use and support

TopSolid themselves recommend that you have a dedicated technical team to master their software. With the flexibility of the software comes complexity, and design is time consuming.

Good resources but only available if you have a support contract in place.

Free option?

Register with the team at TopSolid for a 30 day free trial.

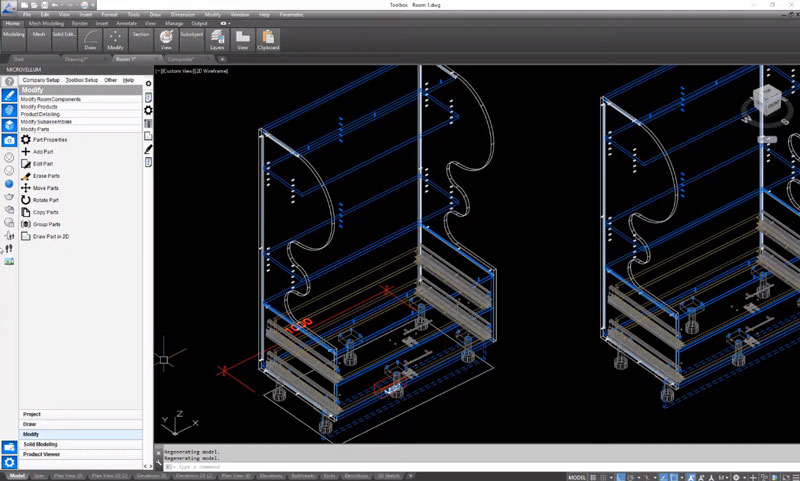

Microvellum

Drawing flexibility vs parametric efficiency

Utilising AutoCAD’s drawing engine, this is in part a CAD based package. You can draw anything, but projects are set up parametrically too. The risk of human error during design is still relatively high due to the drawing foundation, and when defining dimensions and positioning parts.

Although there are over 300 products (cabinets) to get started with, if you want to edit and design your own, a relatively high level of technical knowledge is required, and time to set up the detailed configuration for each.

It is based on a series of Excel spreadsheets, so the functions and formulas of Excel act as the programming interface for the software, which deeper down relies on databases to store all the parameters of your cabinets. It does have tools to help you create your formulas and functions though.

Renders

Microvellum is another nice 3D woodworking design software, it allows you to place lighting, apply material preferences and define the camera viewpoint. Adjusting lighting settings further, for example to determine the correct exposure like you would with a camera, results in good 3D renders.

To achieve photorealistic renders output to AutoCAD’s rendering tools:

Output

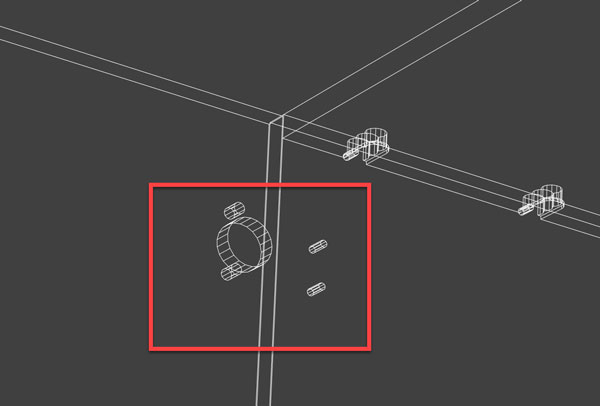

Full cutting list, part by part plans and material and hardware cost reports are available. This image shows the hardware in situ:

Output for an extensive (but not exhaustive) selection of CNC machines is built into the software.

Budget

Check with Microvellum’s sales team for details but this is priced outside the budget of small to medium workshops. Prices vary depending on the level of CNC output you need. Expect to continue to pay for training at least into the medium term.

You also need to have AutoCAD to run Microvellum, whether you purchase via Autodesk or through Microvellum.

Ease of use and support

Very powerful and flexible as it’s based on a drawing package in AutoCAD. To benefit in full strong CAD, Excel and computer skills are a must.

Online training available, plus video tutorials and a user forum. Budget for a lot of technical support if you are working on custom projects.

Free option?

No, but a trial version is available for testing before buying.

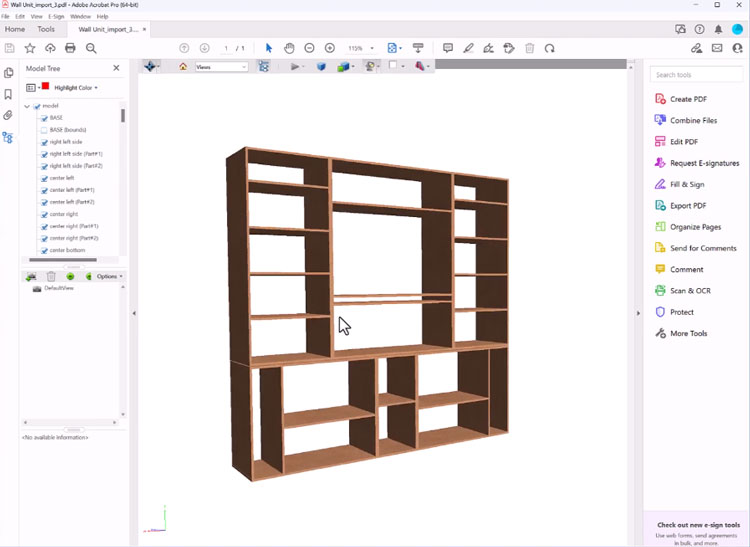

SketchList 3D

Please note, this is only available in English.

There are a raft of very cheap options available, often with very little support, often buggy and extremely limited. Do it the way you’re told or not at all.

Rather than list all these, our final parametric software solution for you to consider is a simple but effective package that sits across the hobby and professional entry level boundary.

Drawing flexibility vs parametric efficiency

The parametric set up is on the slow side, rather than set up the carcass and then configure rules so the parts fit and resize, each component needs to be set up in turn. There are some features like drag and clip into place to speed things up though.

Joinery like tenons, mitre and dados are possible, but if your preference isn’t explicitly in the software, you won’t have the flexibility to fine tune the set up to add it.

If you are just getting started and are willing to conform to the software rather than the other way round, SketchList could still work for you.

Renders

3D renders can be generated as a 3D PDF within Adobe Reader. Photorealistic images aren’t possible though. Here’s an example of that PDF option:

Output

You’ll have access to a cutting list, plans, shop drawings and even basic DXF files of each part. Manually apply toolpaths to these in your CAM software to drive a CNC machine. Unlike other more advanced software, the toolpath application isn’t automatic, a big issue for a busier workshop.

Hardware positions and details aren’t managed. This is ok if you’re working with peanuts or dominoes (it’s fine to manually position those), and jigs for hinges and drawers for example.

For other hardware, exact positioning built into the software is important, and vital for an efficient CNC workflow.

Budget

There are two self evident versions: SketchList 3D Hobby and SketchList 3D Pro.

Both are very affordable, with a single purchase or subscription option, so this might be a good option for a start up workshop. You will likely quickly outgrow the software, but the investment won’t have been large in any case.

Ease of use and support

This software is pitched at hobbyists too, so it is arguably the simplest to learn.

For something so inexpensive, there is a good range of video resources available, and access to a support team too.

Free option?

Yes! Here it comes up trumps. There’s a 30 day free trial that includes all design features. A great way to get started.

Summary and recommendations

We hope this article has helped you to make a decision or at least narrow down your options for further research.

It’s an important decision you want to get right but if your workshop is busy and you don’t yet use design software, it’s vital that you move forward and don’t get caught in a loop of trying to find a solution that does 100% of what you require.

The benefits in terms of an efficient production workflow are huge, the risks of failing to act equally so.

To come back again to the key points we’ve considered, software must offer the design capabilities you require and provide the output efficiently and accurately.

Depending on your business model, here are our recommendations…

Custom commercial and free form furniture

Examples:

- Displays for trade shows and conventions

- Complex commercial projects

- Curved tables, chairs and other projects made of solid wood

If you are charging a lot for one-of-a-kind custom projects, and they include a lot of unusual shapes, a CAD drawing package is likely to be the best option.

The manufacturing output may be harder to access, the design process will be slower, but the flexibility will be worth it.

We recommend:

- Fusion 360: popular and flexible CAD design package at a relatively low price point, the manufacturing output is harder to access but 3rd party extensions are available to help

- TopSolid: high end price point, powerful drawing programme with additional manufacturing add-ons for woodworkers, design is slow but flexible – TopSolid themselves recommend you have a dedicated team for the software

Cabinetry / fitted furniture business

Parametric software will allow you to work with the required panel and bar materials. Design has the potential to be incredibly fast and accurate, and output of the manufacturing files instantaneous.

Professional solutions are available that allow the flexibility to incorporate your construction preferences and hardware.

We recommend:

- PolyBoard: medium price level, powerful enough for large business, fast design process and easy to learn so accessible to small and medium businesses too

- IMOS or Cabinet Vision: high end budgets, more complex to operate but just as powerful, require dedicated technical team

All three include export options or modules to enhance production with photorealistic rendering and optimisation tools as your business grows.

If you think PolyBoard is a good fit for your business, contact us here to arrange a demonstration with a member of our technical team.

You can also download and test PolyBoard here.

Thanks for reading!