Polyboard calculates all your assembly details at exactly the right size and by default leaves no play in the grooves between the panels.

If your CNC router is machining grooves just a little too tight fitting, you can add extra width and depth to grooves to make for an easier fit. This video shows you how.

Video Transcription

In this short video I’d like to show you how to adjust the groove size when you have a panel which is slotted into another one. Polyboard by default will make the groove the exact size of the panel that is grooved into another panel.

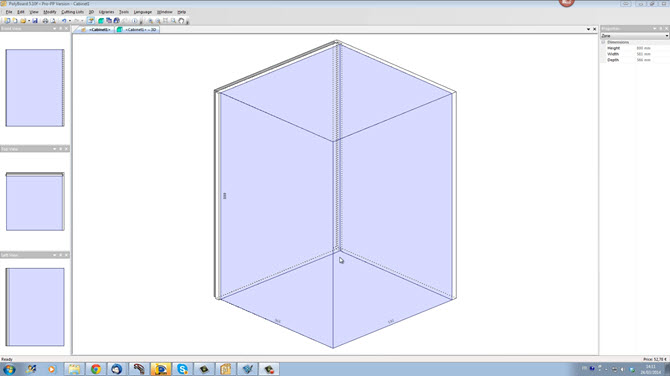

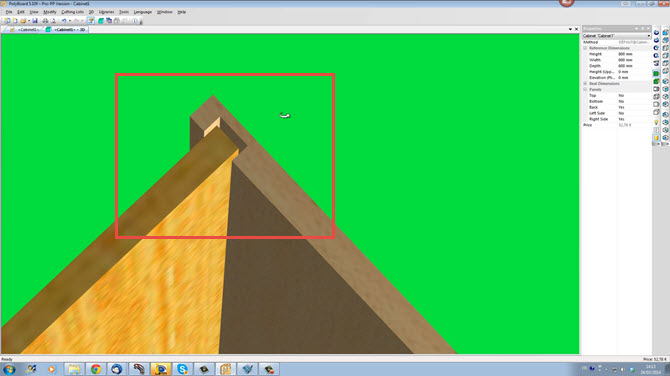

So here we have a cabinet for which I’ve just put in one side and a back.

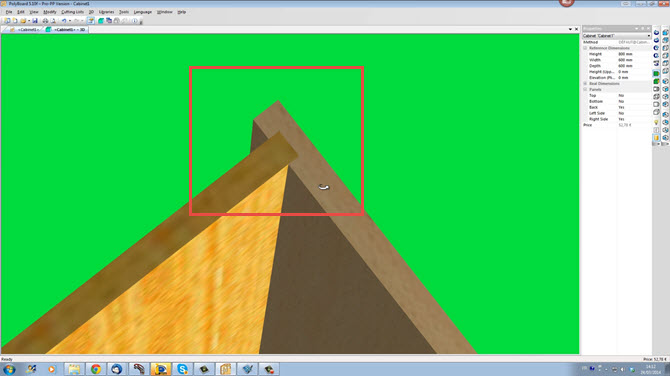

When I look in 3D we can see that the groove is the same size as the thickness of the panel. So, what should I do if, when machining these parts, the fit is just too tight.

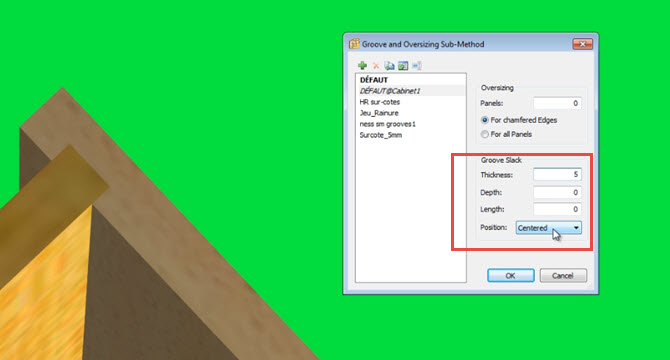

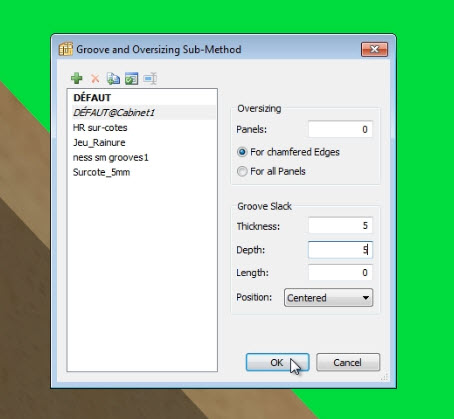

To adjust the two parts I go into Libraries > Sub-Methods > Grooves and Oversizing. The Grooves and Oversizing Sub-Method allows me to introduce slack into the groove. Let’s add in some exaggerated slack to see how this works.

The Groove Slack section is here.

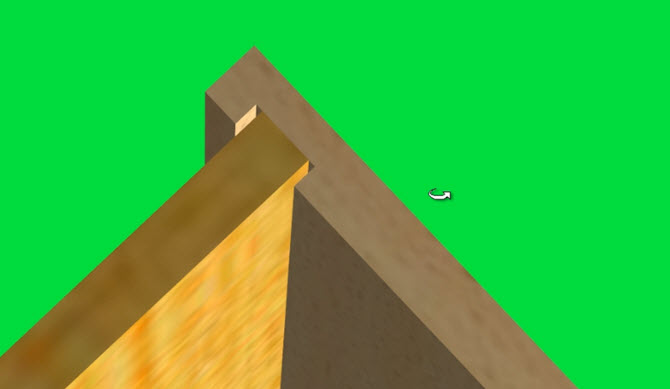

I can put in a Thickness of say 5 mm, and I can centre this thickness on the panel here so it will give 2.5 mm on either side, or I can give it on one side or the other. And if I say ‘OK’ now and apply this to my cabinet, we can see that the groove has been widened by a total of 5 mm and we have 2.5 mm each side.

If I take the same sub-method and put in a Depth slack of say 5 mm, and I click ‘OK’ and apply, I now have 5 mm extra added to the depth of the groove.

Of course, you wouldn’t be using 5 mm yourself, you’d be using perhaps a tenth of a mm to give just enough play so the cabinet side and back would be easy to assemble.

You can find more information on our furniture design software here.

Thanks you very much for watching.