A more detailed explanation of bar optimization set up, including adding user defined profiles from CAD software and angle cut integration.

If you are a wood worker manufacturing parts of fixed length like mouldings, batons and profiled parts.

Or a metal worker assembling metal profiles, RSJs and tubes.

Or if you’re using PVC or aluminium extruded materials for doors, windows.

Or if you are any other manufacturing business that uses constant length bar materials…

OptiCut will tell you the best way to cut your materials, and manage your stock of them.

The initial set up of materials and stock librarier is the same as with panel/sheet material, so please see our other videos on those subjects for an explanation.

This video covers:

- Setting up a bar material (menu item Sock > Bar Materials), in particular defining the section of the bar material, so OptiCut can be enabled to flip the bar and improve the optimization. This is particularly important when your material includes angle cuts.

- Setting up a user defined profile imported from a CAD program as a DXF file polyline.

- Define the way the profile of a bar can be flipped around different axes.

- Adding a trim cut to your bar stock.

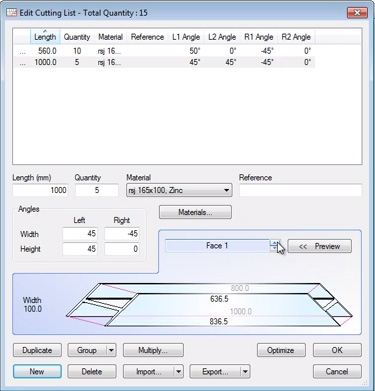

- Setting up a new cutting list including parts with angle cuts.

- Reviewing the 1D cutting maps and sequences following optimization.

- Alternative 3D view of optimization.

- Deduction of cutting list from stock and addition of off cuts to it.

You can find out more details here on our sheet cutting optimization software.