This commercial project shows you how a professional workshop partnered with one of customers to design with the free version of our cabinet design program Polyboard, then outsource cut and machining of the parts.

These parts were delivered back flat packed completely ready for assembly.

The project was run by Lee Ferris and the team at Hutton Timber Products Ltd. It was a large bar install for a sports club and included a lot of cabinetry.

Lee used the free version of Polyboard, with full access to software design advice whenever he needed it on our Wood Designer forum, or via screen sharing sessions.

Here’s a comment from Dean on the project:

We machined and edged 41 10ft x 4ft sheets and sprayed all lacquered panels required for the back fitting.

We delivered it 2 weeks ago and have since had a call to say they are impressed.

This was a great use of Polyboard as we managed all the machining and edging in 3 days with just 2 men then 2 days to spray and pallet ready for delivery. All panels were stickered and along with exploded diagrams, this would of been impossible without Polyboard so very pleased with it.

Dean Price, Tees Tech Joinery

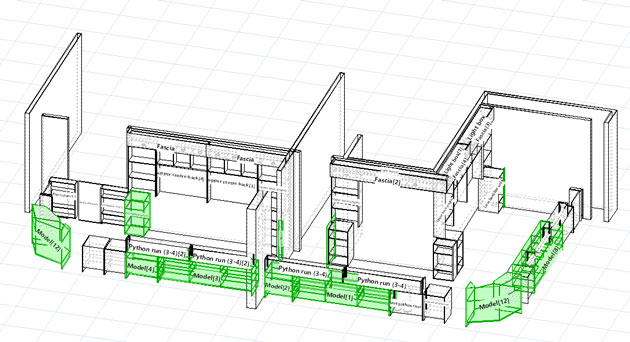

This is a view of the project in Polyboard, showing both side of the bar either side of the central partition wall:

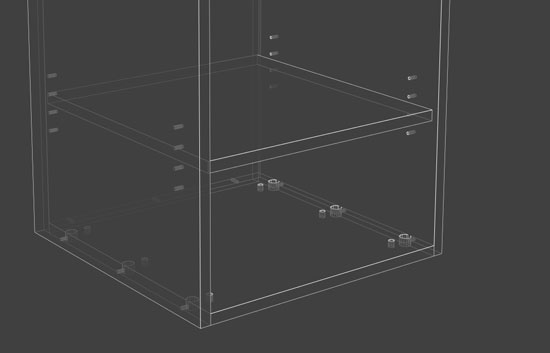

And here’s a close up in wireframe of a cabinet showing the machining for the Raffix connectors:

Here’s what Lee had to say:

In the past I had to draw the project in SketchUp or AutoCad then size up all the panels required, including a schedule showing the grain direction and where edging was required. I would send this off to a supplier to get the parts cut.

Then when you got it all back, we would have to do the jointing, with biscuits for example. The process was prone to error and pretty slow.

This time, I designed the project in the free version of Polyboard and sent it to Dean at Tees Tech Joinery. They cut and edged all the panels and delivered flat packed along with machinings for Raffix connectors so you could assemble easily and quickly.

The whole process worked very well, was faster and cut down on human error, and so worked out cheaper.

Lee Ferris, Hutton Timber Products Ltd

Tees Tech Joinery use SCM CNC machines with a Biesse edgebander, spray booths and work out of a really nice showroom complete with design centre. This features Polyboard on a big screen to present to clients, which we think is a super idea and Dean tells us works very well.

As well as our Polyboard cabinet design software, they nest using our OptiNest software for a very efficient workflow.

can i get ur cabinet software for free

Hi, please register for free here, then you’ll be directed to the download page.

This page on our CabinetFile service explains further how to access the software without buying.

Thanks

I would like to see more of what this free software can do as far as shop drawings and submittals

Hi Cornie, you can output 100% accurate dimensioned 2D drawings (and 3D presentations) and automatically calculate the costs of your projects. Please register for free then go to the Polyboard download page to install and test the software. There are some good overview videos to watch and follow through on the same page too. Thanks, Stefan

I received “Free Cabinet Software + Manufacturing Service”. but I live in México, do you have cnc suppliers here?.

Thanks

Hi Rafael, thanks for your message. No unfortunately we don’t currently have a supplier in Mexico. As an alternative, and if you don’t want to actually buy the software outright, you can sign up to Premium Support and use the free version to get your cutting list, plans and DXF files to run a CNC. Then take those to a local supplier who will still be able to cut your parts for you. Thanks