Wood Designer forum

drawer runners|Forum|WOOD DESIGNER

October 4, 2012

Hello Terry,

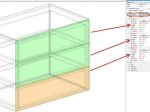

Well, I looked at your drawers in your son’s wardrobe, they are set up so that all the drawer fronts are of equal height:

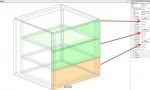

If you set the distribution method to “identical zones” all the insides of the drawers will be calculated to have the same sized parts, like in this drawing:

So you can see that either you can ask PolyBoard to automatically calculate the drawer fronts all the same so that the outside of the furniture looks regular, this is the option “identical heights”, or facilitate the making of the drawers by making all the drawer components identical using the option “identical zones”.

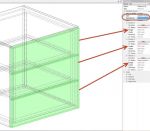

You can ask PolyBoard to make draws a specific size by using the “individualised parameters” in the multiple drawer dialogue box:

So to conclude, you can choose between nice aspect and having all the drawer fronts equal, or easy construction and have all the inner drawer components equal.

Or of course, choosing that specific height of each drawer and get everything different.

Don’t worry about taking time to learn all this stuff, I know it can be quite confusing in the beginning with so many different things to think about and to understand, but you’ll see that once you get the hang of it, you’ll find it becomes pretty much second nature.

I hope this is helpful, if you need more explaining, tell me and I’ll try to do a little video tutorial.

All best for your next projects,

Ness

Thanks Ness

Re the internal drawer box height the cabinet that I meant to refer to was the drawer box on my sons wardrobe. You gave me some tips before about changing the reveals where the drawer box front meets the applied front. I used this tip but it made the top drawer quite a bit smaller! (is this just standard) from the picture you can clearly see that there is room for the top drawer box to be made at least the same height as the other two.

Im probably being fussy….sorry

Terry

Thanks Mark……yes some people just get things. To be honest Ive found it quite difficult learning the software, but on the upside I am finally remembering things. As Ive said before I dont do the cabinet/furniture work day in day out as I do general building work as well but im finding the more I do it the easier Im finding using the software.

The real upside to Polyboard for me though is once you have got your general way of constructing things in the system things are pretty simple and you can just go back to them. Its all a methodical process. What I really like about the software is how versatile it is…….and you only really understand that as you begin to learn it.

Cheers

terry

October 4, 2012

Hi Terry,

Good to see that you’ve figured out the drawer runners and how to set up the rules.

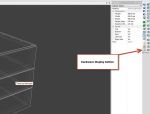

To make the fittings show up in the 3-D display. Make sure the hardware button is on.

This option turns the hardware display on and off so that when is lots of hardware you don’t need to show or calculate hardware, you can turn it off and greatly reduce the calculation time for 3-D display.

For editing your projects it’s far better to use sub methods and manufacturing methods in general, if possible.

The best way to go about things is to set up a whole bunch of sub- methods that are your general ways of working.

Like that you can just load in a cabinet any cabinet and apply the necessary sub- methods and get it all set up automatically.

Once set up with the specific sub methods you then go into your project and modify any details that will be specific to that project.

The important thing is that you understand the difference between modifying the sub method that is specific to your active cabinet and the sub method that is a general sub method that you can apply to any cabinet.

The sub method that has a name and then @cabinet name is a sub method that is only specific to the cabinet you’re working on. This stops you modifying the general sub methods library while modifying your individual cabinet.

If you want to modify the sub method library you have to click on the library element and modify that specific element and not the individual cabinet method.

I’m just uploading another little video on how to use manufacturing methods and I’ll post to you when video is uploaded.

For the drawer box heights your project seems to have all the facade elements calculated to be the same.

PolyBoard will by default calculate automatically all the drawer fronts the same height.

With all the fronts the same height, the inside of the top drawer will be different than the others.

You can recalculate the drawers so all the drawers insides are the same.

To do this, change the distribution mode from identical heights to identical zones.

This enables you to machine all the inside drawer parts the same but of course will make the facade elements different.

If you need specific heights for a particular drawer, you have to individualise your drawer separations.

Hope this is helpful,

all the best,

Ness

Ness I think Ive figured out the drawer runner hole thing. Downloaded and had a look at one of Marks templates and it had a slide fitting in the fittings link (even though there were no slides on that particular project)….think it was the utility room one. Anyway had a look at Mark fittings and rules etc and watched Ness video again and it all made sense to work out the unique rule thing which was baffling me.

One question Ness or Mark I noticed that when I apply a new fitting from a sub method it takes away all the other fittings in the 3d mode. Ive noticed that Mark has grouped all his fitting links together on the utility room project so all the fittings show up.

So is it best practice to use sub methods etc or just throw in the fittings links as and when you need them? Is there a way for all the fittings to show up in the 3d mode? I.e hinges. drillings etc. without having to group them all under one fitting rule?

Ness still struggling to with the drawer box heights……In the project file I sent you….you can see that the top drawer is smaller in height than the other two drawers…..could use some advice on this.

Mark BTW I also nicked your Overlay blum hinges, I thought it would be rude not to.

Tel

1 Guest(s)