- Home

- Help Centre

- PolyBoard tutorials

- CNC integration

- CAM software integration with PolyBoard to run your CNC

CAM software integration with PolyBoard to run your CNC

Our PolyBoard CNC design software directly outputs native CAM software files for a range of popular brands of CNC including Biesse, Homag, SCM and Felder. Click here for an explanation of this set up.

However…

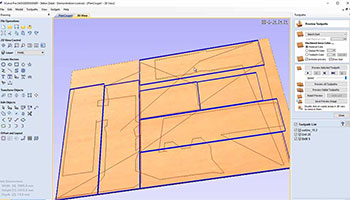

…for CNC machines that use standard GCode, PolyBoard outputs DXF files

These DXF files require CAM software to add the tool paths and generate the GCode for your machine.

This integration is the most common we see.

If you are manually inputting the sizes of individual parts and tooling requirements into your CAM software, you’ll know this is error prone and takes a long time.

With PolyBoard, complete your design then send all parts with full machining details to the CAM software in one go, which in turn outputs all the code for your machine. The process is very fast, accurate and virtually automatic.

DXF is the industry standard file format that contains the drawings of your design. Specifically, these DXF files are layered, with each layer having a custom name (configured in PolyBoard) that corresponds to a specific tool set up in your CAM program.

All these layers are interpreted by the CAM software to provide your CNC with the GCode to cut the parts and to add all the machining (holes for hinges, drawer sliders, cam & dowels etc).

Click here for more information on:

GCode is the generic name for the most widely used control language for CNC machines

These machines include those by:

- Thermwood

- Laguna

- ShotBot

- And lots more, many of which are built in China

The GCode file extension varies but includes:

- .nc

- .cnc

- .cn

- .iso

All CAM software solutions will accept PolyBoard’s DXF files. If you already have CAM software working with your CNC, this is all you need to ensure that PolyBoard will work with your machine.

If you are planning to buy CAM software for a new CNC machine, it needs to accept DXF files. The CAM software also needs to output the correct GCode for your machine.

VCarve is an affordable solution that offers a huge number of GCode post processors. If they don’t have a post processor for your machine already, they will create one for you. Click here for more details on VCarve.

The video below shows the integration of PolyBoard with VCarve and a GCode CNC machine. You can see that it only takes a minute or two to get your design through VCarve, to add the tool paths and process the GCode to run your machine.

Please note, if you have a 4- or 5-axis CNC or use a drill bank or lateral/edge drilling, you may need an alternative CAM package like Alphacam, Enroute or EasyWOOD.

Please get in touch if you’d like to discuss what CAM software is best for you.

Using PolyBoard with CAM Software (in this case VCarve) to run your CNC machine

Check out this video to see how quick and automated the process is.

ArtCam is another inexpensive CAM option that also works well with our software but there are many more. There are also high end CAM packages that will run with our software. AlphaCam is one example, click through to this page to see the Alphacam configuration up and running.

In general the only machines that will struggle to run with our software are older machines that use their own propriety machine code and don’t accept standard GCode.

What about nesting?

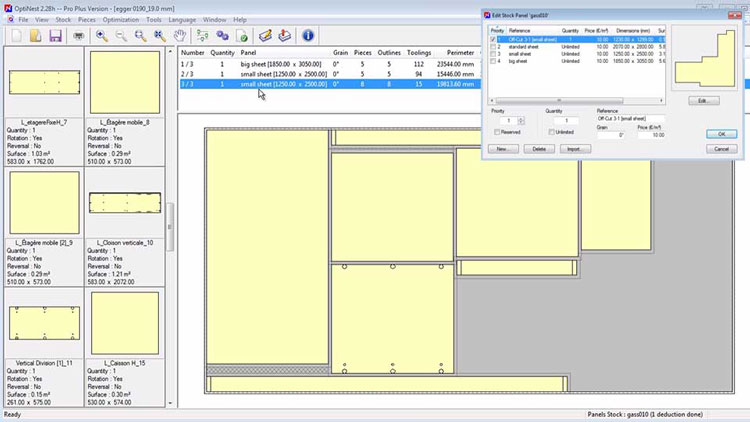

If you have a point to point machine, you can use OptiCut to optimise your cutting list before machining each part on your CNC. But you only need PolyBoard and the CAM software to run the machine.

If you have a nesting machine, you have 2 options for managing the nesting…

1. Your CAM software has nesting capability, like VCarve or AlphaCam for example

In this case, your CAM software can manage the nesting itself.

2. You add specialist nesting software into the production process

Our OptiNest software adds extra functionality on top of many CAM nesting packages, such as labelling and stock management. If your CAM software does not nest, you must add some kind of nesting solution.

Please contact us if you would like us to discuss the best configuration for you.

Click here for details on OptiNest

Point to point vs nesting machines

Test PolyBoard’s output with your CAM software and machine

The download below includes sample DXF files to test with your CAM software then process the code for your machine. If you would like actual GCode files, please contact us with details of your machine.

You will be able to load the machine code into your machine interface and quickly see if your CNC is compatible with the code.

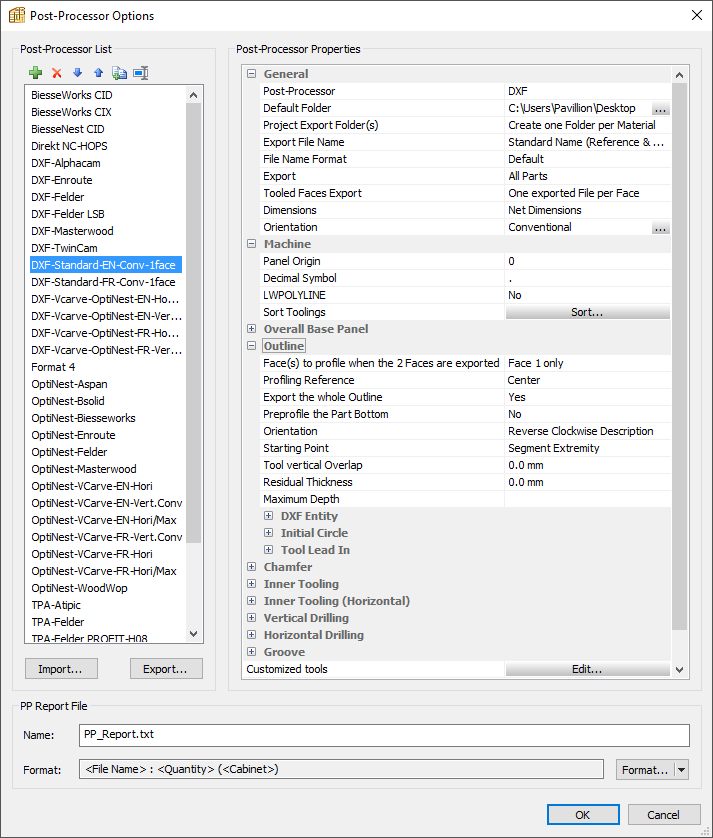

Please note that you will not be able to fully cut and machine your parts. PolyBoard’s DXF post processor will first need to be set up with the right tool path templates and options for automatic CAM processing. We can help you with that if required.

We can also arrange a screen share session to confirm the compatibility of your CAM software and CNC with PolyBoard.