- Home

- Help Centre

- PolyBoard tutorials

- Essentials

- Manufacturing output

Manufacturing output

PolyBoard Essentials: Previous | Next

PolyBoard has been created as a design to manufacturing solution. It offers instant access to all manufacturing output which is dynamically updated as you design.

We have detailed advice on the output options in the Help Centre here:

Manufacturing output (non CNC)

Sample output

Examples of the available output can be found here:

Manufacturing output options

Here’s a simple overview of what’s available:

Cutting lists

Sorted by cabinet or material, also available as a configurable csv file.

Part by part plans

Plans of every part available for printing including machining coordinates and cut angles.

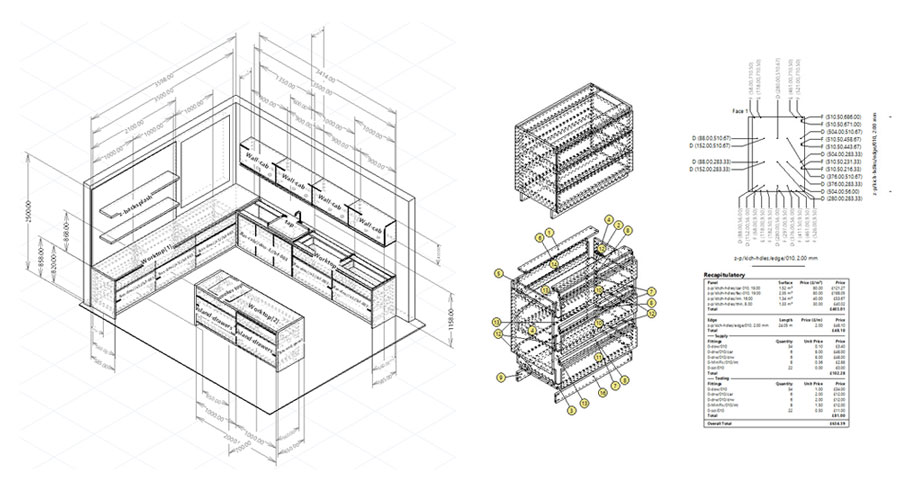

Dimensioned drawings

Fully dimensioned isometric, plan and cut through views of individual cabinets and complete room layouts.

Labels

Highly customisable including barcode options.

3D renders

- Textured and wireframe views

- Add shadows and other lighting effects

- Rotate to any angle

- Zoom in and out

Cost and material usage report

Including panel, bar and edging materials used, hardware and machining costs.

3D DXF and 3DS output

For import to CAD software.

CNC output

- Files of every part in industry-standard 2D DXF format, compatible with all CNC software

- Additional native file format CNC output for a range of popular CNC brands

- Multi post-processor feature to split CNC output across different machines

Catalogue mode

For bulk manufacture from your model library.

Seamless integration with OptiCut and OptiNest

For cutting and nesting optimisation respectively.

ERP output

Highly customisable output for your ERP solution.

Hardware list

Details of all hardware used in your project, exported as a .txt file.