- Home

- Help Centre

- PolyBoard tutorials

- CNC integration

- VCarve integration with PolyBoard and StairDesigner

- Home

- Help Centre

- StairDesigner tutorials

- CNC integration

- VCarve integration with PolyBoard and StairDesigner

VCarve integration with PolyBoard and StairDesigner

Here we focus on VCarve, but the same integration applies to Aspire (both developed by the same company).

Update: we have now partnered with Vectric so you can buy VCarve Pro direct from us, either on its own, with any of our other software packages, or already set up with our CNCs.

Click here for details and to download VCarve

Our software integrates with any CAM software that accepts DXF files.

This includes VCarve, one of our favourites as you’ll discover below.

Why so good?

- VCarve offers fast and reliable integration with our software, tried and tested by our customers

- Available at a very affordable price

- Lots of other features including sign making, wood carving and engraving (3D capabilities with Aspire)

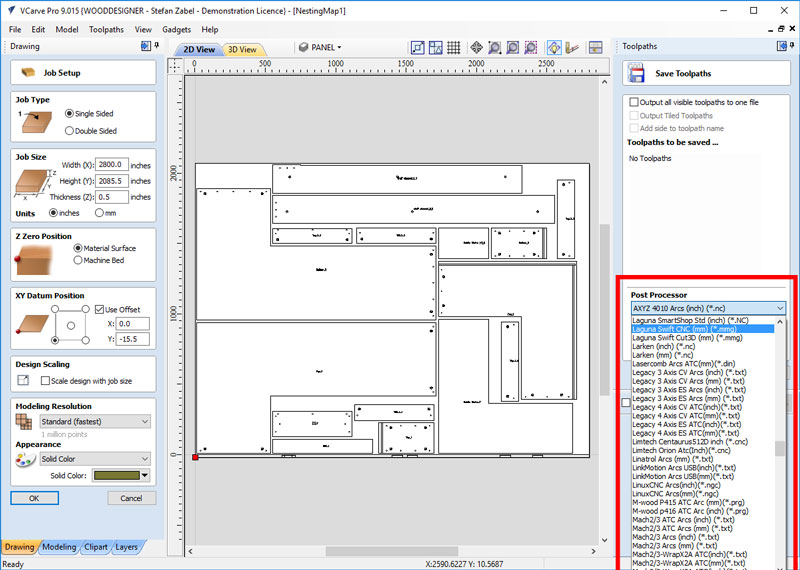

- Comes with a huge range of post processors for virtually all CNC machines

- Basic nesting module as standard

- Great support from the team at Vectric

VCarve comes with a large number of post processors for 100s of CNCs already. If they don’t have what you need, the Vectric support team can almost always create a new post processor for you. Contact Vectric for confirmation.

How the configuration works…

PolyBoard and StairDesigner output layered DXF files which can be set up to match your particular production methods.

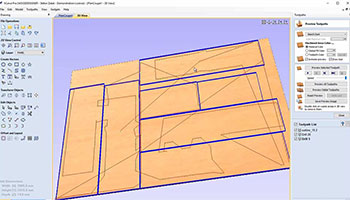

These files are loaded into VCarve as a project. You then apply a pre-configured template for PolyBoard furniture parts, or for StairDesigner strings, or StairDesigner steps and risers for example.

Then select the calculate toolpath button and generate the code to run your specific machine which will automatically cut all parts (if you have a nesting CNC) plus the complete machining for your hardware.

Watch the video below to see how fast and reliable this process is, so much better than calculating your project by hand or in CAD then inputting part dimensions into your CAM software manually.

PolyBoard to VCarve to your machine in action

This video shows the integration with PolyBoard. The same configuration applies to StairDesigner.

Please note, VCarve Pro works predominantly with 3-axis CNC machines. It may not be compatible with machines with drill banks, or those that edge (lateral) drill.

For high-end CNCs with drill banks and 4- and 5-axis machines, you will probably need to replace VCarve with CAM software like Alphacam, DDX EasyWOOD or Enroute. These will allow you to use PolyBoard’s DXF output to edge drill.

A word about nesting

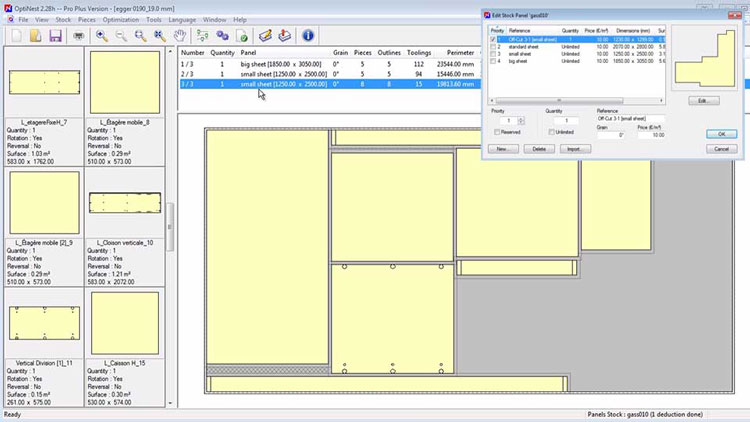

If your machine is point to point / pod and rail, it’s a good idea to optimise cutting of your panels using an optimisation software like OptiCut which integrates seamlessly with PolyBoard. If however you have a nesting machine, you need to nest the parts on your machine as well as machine each part.

VCarve comes with a basic nesting tool built in, but if you want extra professional features like labelling and stock management, please take a look at our OptiNest solution to take your production to the next level.

Click here for details on OptiNest

And here for information on the differences between point to point and nesting machines.

Want to test things out first?

Download the PolyBoard and StairDesigner test files below to test with VCarve.

Manufacturing sample files – PolyBoard

Manufacturing sample files – StairDesigner

The specific files you’ll need are the part by part DXF files.

Please note, to fully set up the configuration you will need to load up a template into VCarve and adjust the DXF output settings in our software to match your machine’s specifications. We can help you with this.

We are also happy to test the set up and answer your queries via a screen sharing session. Please contact us to arrange this.

Contact us to request a compatibility test

Click below for more details on our integrations for: