When building a staircase, one problem may confuse you more than most: how do you cut stair stringers?

Don’t worry, we’ve got the answer for you right here. First though, let’s define what a stair stringer actually is.

What is a Stair Stringer?

A stair stringer, also known as a string or stringer board, is the casing of a flight of stairs into which the stair treads and risers are fixed. If one side of the stairs is against a wall, the stringer that connects the treads and risers is known as a wall stringer.

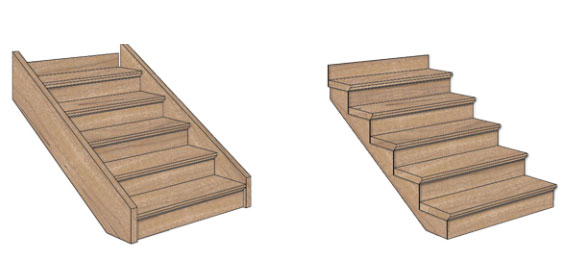

Stringers can hide or expose the steps based on design preference. They are known as closed stringers and cut stringers respectively.

Stair Stringers: Closed (left) and Open (right)

Designing a Stair Stringer

The first thing that you need to consider is how the stringer will attach to the landing at the top of the staircase. It must either attach directly to the rim joist (so that the top step is the same level as the landing) or to the underneath of the landing (so that the landing serves as the top step). This will affect the length of your stringers.

If attaching them underneath, the stringers must be attached to the joists or blocking placed between joists and the ends must be cut long enough to reach the framing.

You must also consider the size of the stair risers and treads, as those will affect the angles that will be cut into the stringer. When marking these onto the wood that will become the stringer, use a framing square fitted with stair gauges. This simple tool accurately marks the identical notches quickly and easily.

You simply clamp one stair gauge on the square’s tongue for the rise measurement and another to the square’s body for the tread dimension. Then you lay it onto the wood, with the gauges placed against the board’s edge to mark the tread and riser of the first step. Repeat until finished.

Cutting a Stair Stringer

When cutting a stair stringer, you must cut the marks that you just made using a circular saw, ensuring that you don’t go beyond the lines, and finish the cuts using a jigsaw or handsaw. Then, cut the bottom of the stringer to an amount equal to the thickness of the tread.

Once one stringer is cut, use it as a template for the remaining ones (to save you time and reduce errors). When all stringers are cut, screw them into place and check that each step is level using a spirit level. Use a block plane to shave down any mistakes.

Reducing your Effort and Improving Results

Alternatively, if you’d like to save yourself from having to manually cut stair stringers (particularly if you’re a professional and this isn’t a one-time job) you could invest in some professional stair design software to reduce your physical labour.

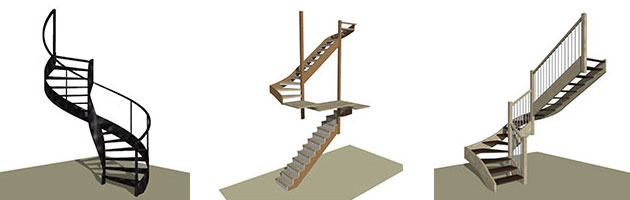

All you do is design it via our programme, which will save you tons of time compared with hand-drawn designs and allow you to view the staircase in 3D.

3D stair designs in StairDesigner

If you want to cut the pieces yourself, you can either buy the full version of StairDesigner or use the StairFile processing service. We will then process and send back your cut list and plans.

Our programme can also reduce your mental labour by automatically calculating the stair risers, treads, and stringers for you and giving you access to a wealth of expert technical support via our site or the opportunity to get a one-to-one training pack to improve your business.

If you want to improve and simplify your woodworking business, why not try StairDesigner today?