Let’s start with the title of this article then.

The kitchen project we’re highlighting here took 2 days instead of the normal 8.

That’s 4 times faster than previously.

From design to assembly using an integrated CNC and software solution.

Here’s a summary of each stage of production:

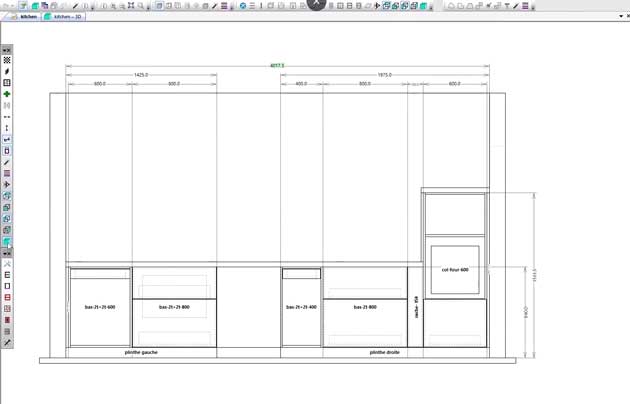

1. Design in Polyboard

Parametric design of the kitchen project including the machining details for all hinges, drawer sliders etc. 3D and plan images are also available for the customer and assembly team.

Please click here for further details on the benefits of our professional kitchen design software from design speed and flexibility to instant access of manufacturing output with full hardware management.

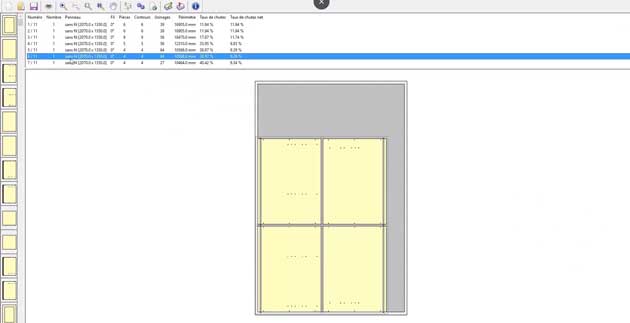

2. Parts nesting in OptiNest

All parts are exported to OptiNest which creates optimised nesting maps to minimise material waste and speed up machining for all materials in the project.

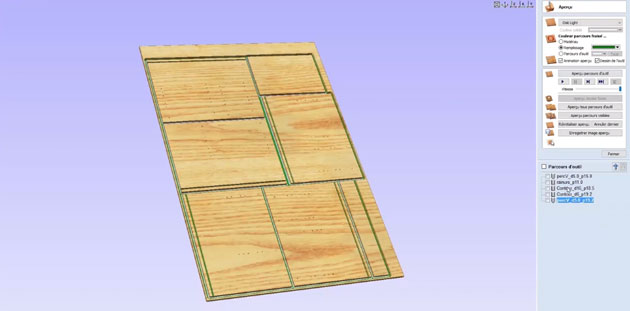

3. Output of machine code

The nesting maps are processed by VCarve which produces the machine code to run the CNC machine.

4. CNC nesting manufacturing

The nesting CNC is set up with the panel material. Parts are cut and machined in a single operation.

5. Preparation and assembly

Edging and assembly and finally install of the kitchen.

As you can see, the overall process is error free and much faster than design by hand or with a CAD package followed by a non CNC manufacturing process.

Here is a transcription of our interview with David Giroud-Suisse who managed this project:

We started at 9:00 in the morning with the set up, spending some time to get the panels and CNC ready to go.

By late morning ¾ of the panels were machined, they were all finished by early afternoon.

By the end of the day, all the panels had been run through the edgebander.

The kitchen was assembled the next day including: drawers; facades; worktops.

I think that this type of machine and the Wood Designer offer is well suited to small businesses, even as small as those with 1 to 2 people, not just for big companies. It works because it frees your time to do other things.

It’s a great help if you’re into cabinet making, staircases, signage, and railings and fencing.

It’s suitable really for a large range of workshops.

CNCs I think are the future.

It’s great to hear this production process can work just as well for small and medium businesses as larger industrial manufacturers.

The software is easy to learn and fast enough to use so you don’t need a dedicated technician to use it, you can do it yourself.

And a nesting CNC is low maintenance too, once it’s set up to run the parts are cut and machined in one process. No need to load up the part and design file one at a time for machining as you would with a pod and rail set up.

Further details on our CNC woodwork configurations can be found here

Bonjour

Je suis intéressée pour savoir ces logiciels dites moi comment puisse les utiliser.

Merci khadija/Maroc.

Bonjour Khadija,

Merci pour votre message.

Je vais vous envoyer des informations directement sur votre adresse email.

Bonne journée

Carole