How to combine CNC cabinet design software with your machine to boost the speed and accuracy of production, top software recommendations and common mistakes to avoid.

After investing big in a CNC to manufacture fast and accurately, it’s vital that you can both design your cabinetry and get the details to your CNC efficiently, or you’ll just be moving the bottleneck in your workflow somewhere else.

And you’ll never see a good return on your investment.

The overall design to CNC solution is inherently complex and can open up more questions than it answers:

- Will the software integrate with my machine?

- What’s the difference between cutting my parts and machining?

- Can I use my CAM software to design cabinets too?

- What files does my CNC need?

- Do I need to worry about nesting my parts?

But get this right and you can transform production for the better. Move from design concept to fully machined parts, 100% accurate and ready for assembly, in record time.

With PolyBoard we cut a kitchen out and put it all together in 2 days.

That would have been a 2 week job before.

Gareth Ellis, Welshpool Kitchen Company (CNC production with PolyBoard cabinet design software and VCarve CAM software)

Below we’ll cover the best options available to you, but start with some common mistakes we need to avoid.

I want a single CNC cabinet making package to run my machine

It would be great if you could design your cabinetry in a software solution, and have that automatically generate the machine code for your CNC so it can cut and machine the parts.

Unfortunately, no single software can do this, whatever the sales copy says. Dig a little deeper and you’ll always find extra modules or software that is required to make the full integration work.

There are just too many differing functions and output requirements needed for one software solution to do it all.

Can I just use my CAM software?

If you have a CNC you must have CAM software. This generates the actual machine code the CNC needs to run, the final step in the process.

In theory you could manually input the dimensions and required tooling operations for each part into the CAM software. This is normally possible and does generate the code to run your CNC.

But this is very slow and error prone, exactly what CNC production is meant to avoid.

When set up correctly, purpose built CNC cabinet design software should automatically send the part dimensions and the machining data for your hardware to the CAM software which then automatically generates the machine code.

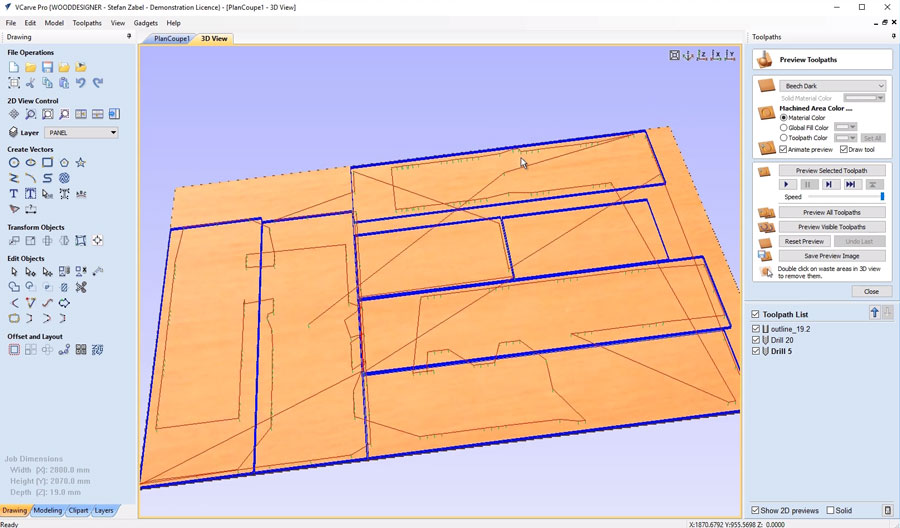

If you’re looking for CAM software for a new CNC consider:

- VCarve Pro, integration with a vast range of 3 axis nesting CNC machines, set up tool templates to recognise the output from your cabinet software and auto apply the correct tooling operations

- Alphacam, Enroute and EasyWOOD; more advanced solutions to manage 4 and 5 axis CNCs

So, what’s the best option for CNC cabinet software?

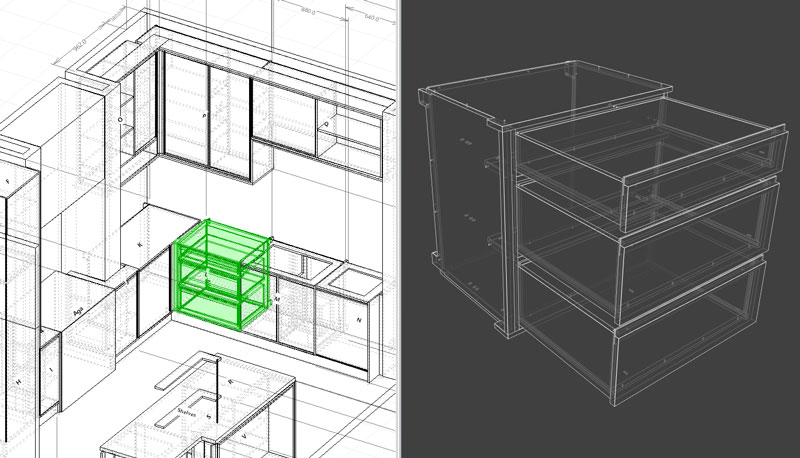

To work this out, let’s break the design to manufacturing process into three stages:

- Design your cabinets (using drawing based or parametric cabinet software)

- Output a data file for each part which includes the part dimensions along with machining details for the hardware

- Convert this part data into the machine code to run your CNC (using CAM software)

Manufacturing output

So, we absolutely must have cabinet software that outputs those part by part details.

In fact, most CAD packages are drawing based and don’t readily (if at all) output manufacturing files like a cutting list, plans of each part and, crucially here, a file of each part.

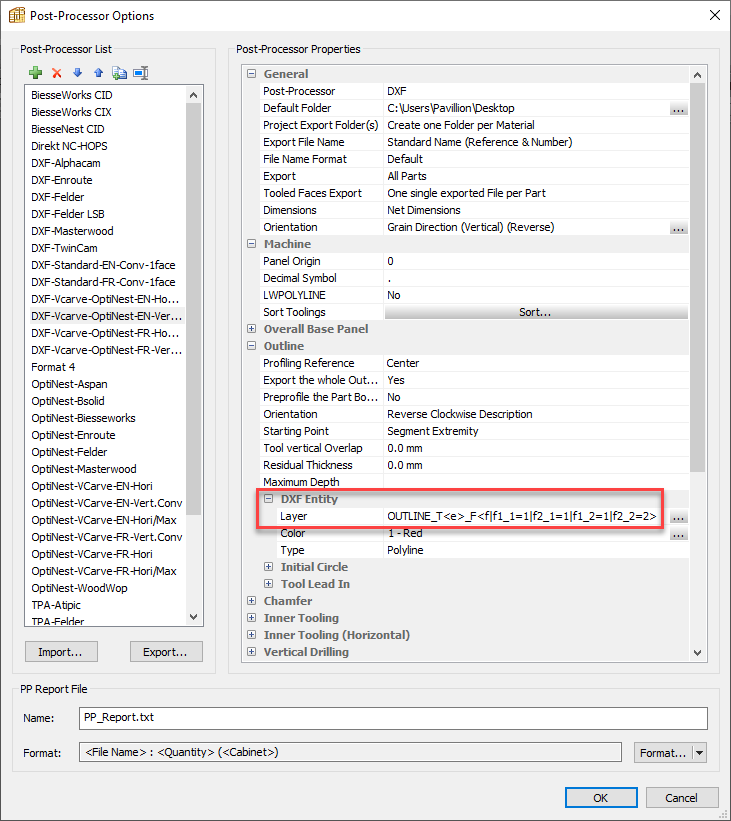

Correct file formats to look for:

- All CAM software will accept industry standard 2D DXF files so make sure your cabinet software offers this output, a single DXF file for each part

- Some cabinet software will also output part files in the native file format for specific branded CAM software e.g. MPR files for Homag’s woodWOP CAM software or XXL files for SCM’s Maestro CAM software

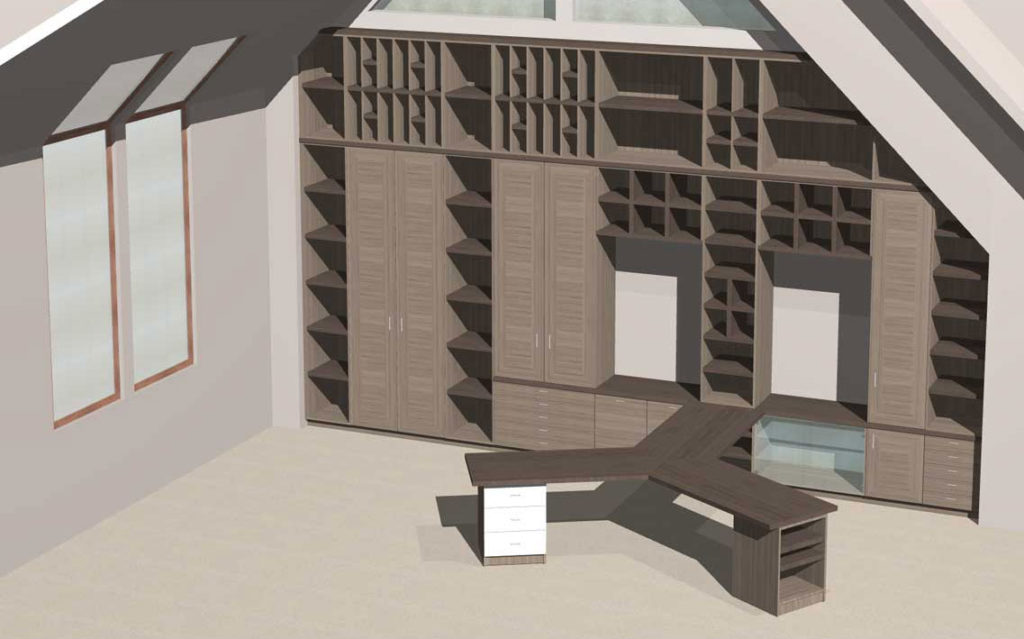

100s of CAD packages allow you to design pretty much anything you can imagine, and create detailed 3D renders.

They can have significant value to your business, but don’t provide the manufacturing output required for CNC production.

Tool path automation

A good cabinet software will also output tool path information, so your CAM software can read this and tell the CNC what tool to pick up and use for a specific machining operation, for example to:

- Cut the part out

- Machine the hinges

- Machine the pilot holes for drawer sliders

To achieve this, DXF files should be layered with each layer including the geometry and an identifier (the layer name) corresponding to each specific tooling operation.

Important! This functionality is a huge time saver, and maximises the benefits of CNC production.

Drawing vs parametric cabinet software

In essence, this is drawing with a computer vs defining the parameters and components of your project and letting the computer build the model.

Drawing based CAD packages:

- Huge design flexibility

- Slow and error prone as you are essentially drawing on screen

- Editing your design often requires you to go back and modify individual components so again it’s easy to make a mistake

- Typically limited or no CNC manufacturing output

Parametric solutions:

- Always somewhat limited design flexibility

- Good professional packages still offers a lot of flexibility

- Very fast and 100% accurate

- Editing your project is much easy too, resize a cabinet and all components resize automatically

- More likely to offer CNC manufacturing output

Best cabinet making software for CNC production

Let’s take a look at some specific solutions now we know the must have features.

Hot picks

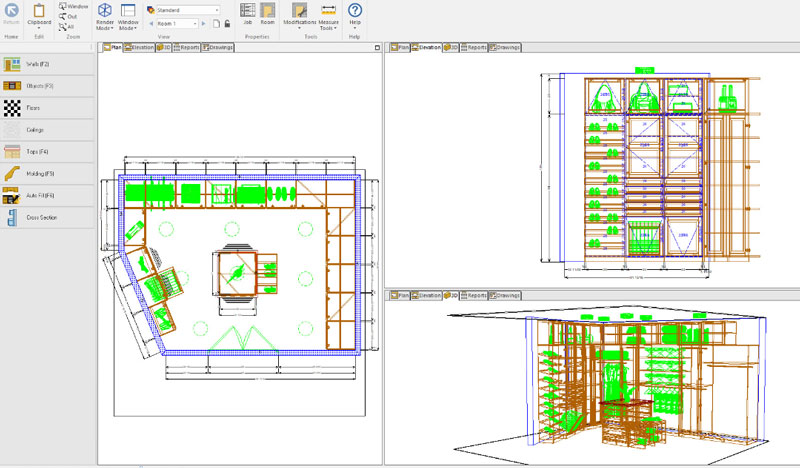

PolyBoard

- CNC manufacturing output – layered 2D DXF files and native file formats for Biesse, Homag, SCM/Morbidelli, Felder, Vitap, Brema and NC-HOPS machines

- Automatic tool path application built into CNC file output

- Parametric, design fast and error free

- Powerful pro software but relatively easy to learn, target market is small to medium woodwork businesses

- 3D presentations available, 3D DXF and 3DS output can be sent to a photorealistic rendering software if required (KeyShot and pCon.planner for example)

- Integrates with a range of optimisation software including OptiNest and OptiCut

Click here for more details on PolyBoard

Cabinet Vision

- CNC manufacturing output with add on modules

- Parametric engine

- Expensive but powerful feature set

- Complicated to learn but worth it if you have a dedicated technical team

- Photorealistic rendering add on module

- Optional cutting and nesting add on modules

Other options

Very low cost parametric software

- These tend to have very limited features, where you choose from short lists of components, hardware and other construction preferences

- CNC integration if available is often limited, for example lacking tool path information

- Affordable and simple to use but you may outgrow it fast

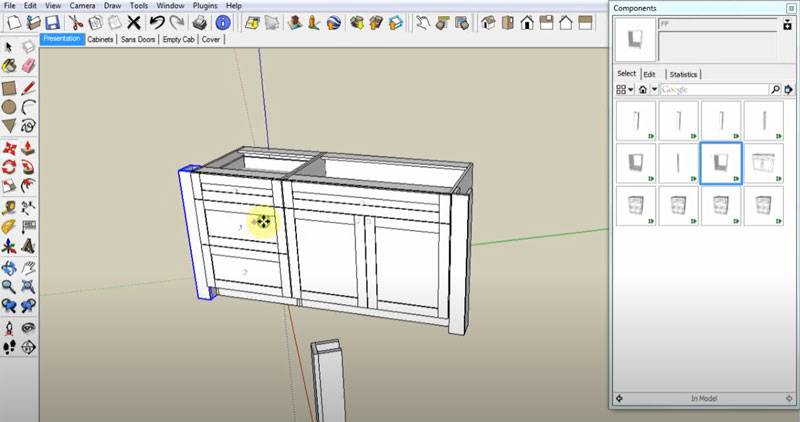

SketchUp

- Drawing based, very flexible

- Manipulate models within complex project environments

- Design and editing is slow, errors more likely

- Cutting list and CNC add ons available (for example CabinetSense) but fundamentally the software is not designed for the production of manufacturing output

CNC supplier in-house solutions

- Some of the major brands offer CNC furniture design software; this isn’t generally their focus so isn’t always as feature rich and well supported as a stand alone solution

- Integrate well with that specific brand of machine

- Not suitable for workshops that use multiple CNC brands, makes changing machines tricky

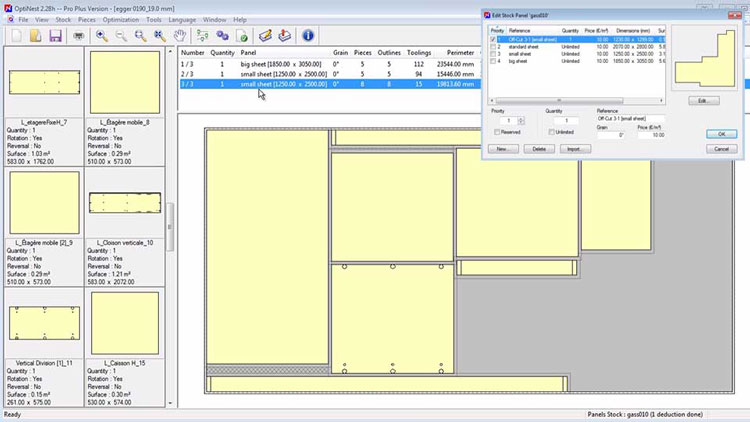

Complement your CNC cabinet software with an optimisation solution

Nesting optimisation software

If you are using a nesting machine, you also must have software to decide how to place the cabinet parts on your sheet material. The cabinet software sends the parts information to this optimisation package which in turn sends optimised cutting maps to the CAM software. Examples include:

- OptiNest, a standalone nesting solution which also integrates seamlessly with PolyBoard and includes labels, stock/off cut management and grain matching

- VCarve Pro and Alphacam CAM software have basic and advanced nesting modules respectively

- Some CNC suppliers offer a nesting module with their CAM software e.g. B_NEST by Biesse

This OptiNest screen shot shows the parts nested on the sheet material ready for cutting and machining (you can see the holes for the hinges too):

The video below highlights the automation and speed of a PolyBoard > OptiNest > VCarve > nesting CNC machine set up:

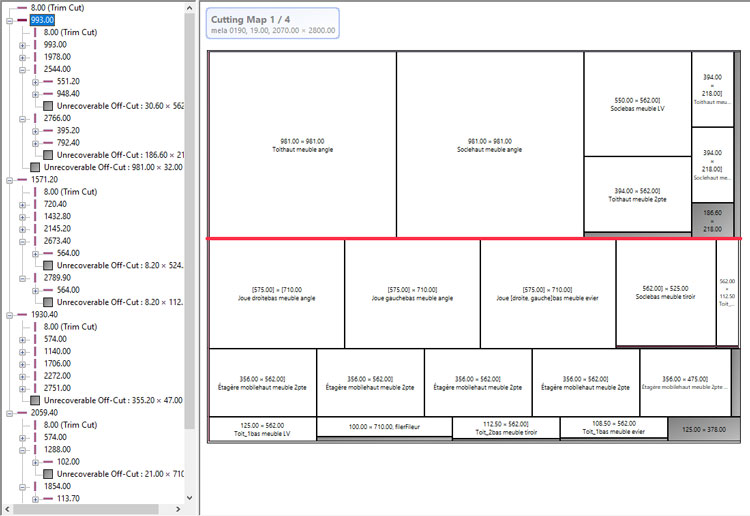

Cutting optimisation software

If you are using a point to point CNC that only machines the parts, you’ll need to cut the parts beforehand. In this case you can optionally have software to tell you how best to cut your parts, or you can manually work this out. Examples:

- OptiCut, like OptiNest this is a standalone solution or can be integrated with PolyBoard, and includes labels, grain and stock/off cut management

- CutList Plus is another well known optimiser you may like to consider which also integrates well with PolyBoard

Here’s a screen shot from OptiCut showing an optimised cutting map:

More on the different types of CNC production

We have more information here on the pros and cons of nesting vs part by part CNC production.

Need help deciding?

First of all, please note that we offer PolyBoard, OptiCut, OptiNest and VCarve ourselves.

We focus specifically on providing design to manufacturing solutions, including for CNC production, rather than other drawing based CAD software.

We’ve tried to honestly compare products based on feedback from our customers and are happy to discuss what’s right for your workshop, even if it’s not something we offer.

If you would like to talk to a member of our technical team, please ring us or use our contact form here.

Very informative, one of the best sites I have visited on this topic. Will be in touch.

Jimmy (Ireland)

Thanks, Jimmy! We’re glad you found our article informative. Feel free to reach out to our customer support at support@wooddesigner.org if you have any questions.

Best wishes, Fatima

Nice post… Thanks for sharing

Hi Michael, thanks for your comment. We really like the integration of PolyBoard with VCarve to output the machine code. This works well for nesting CNC production. All the best, Stefan