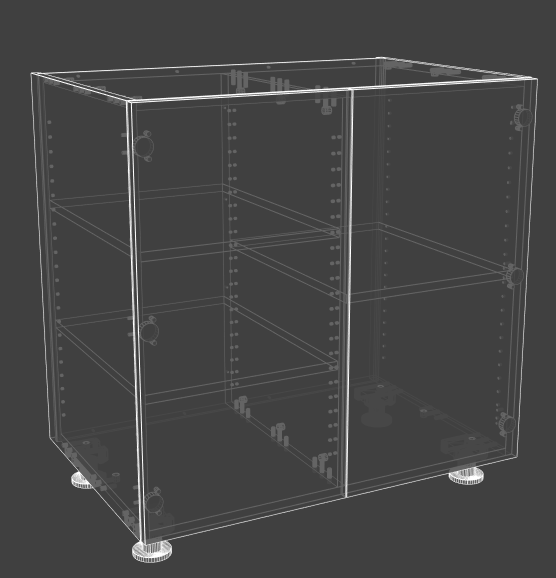

The 32mm cabinet system is a method of construction based on using 5mm diameter holes drilled regularly along vertical components at 32mm increments.

These holes are then used to locate hardware to hang doors and drawers, and to place shelves.

PolyBoard is pre configured to fully manage this system, and includes some advanced features to make hardware placement very easy.

We’ve created a short video overview here:

The 32mm system is a popular method of building cabinets in Europe, typically employing a series of holes in two rows running from top to bottom of the cabinet sides and other vertical separations. For standard hardware the holes are usually 37mm from the edges.

PolyBoard has two methods of application, both accessing the regular drillings feature within the software:

- Global

- By specific internal zone

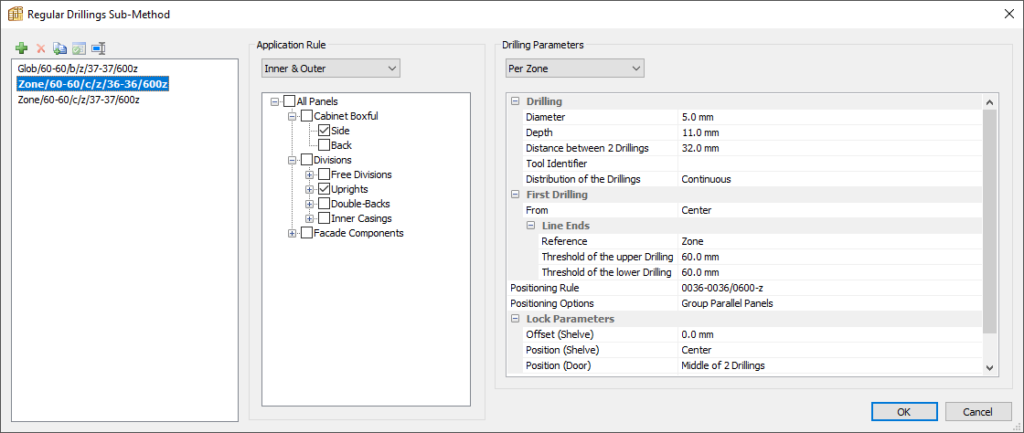

The configuration for both is stored within the Regular drillings manufacturing sub-method. This is set up ready to go within PolyBoard’s Quick Design libraries.

Global

The 32mm system is applied to all vertical components. Add a new upright and the drilling pattern will automatically be added.

To activate the global set up, apply the global sub-method, or an overall manufacturing method that includes this sub-method.

By zone

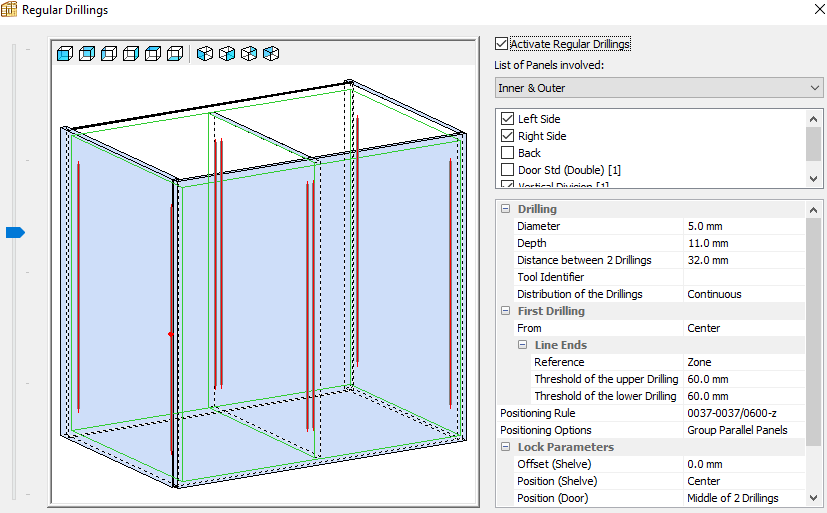

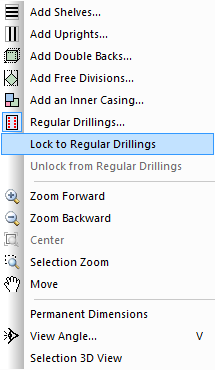

Here you select a specific internal zone of your cabinet to apply the drilling pattern to. Right click over an internal zone in the Cabinet mode editing window and select Regular drillings.

The pop up window includes the settings from the zone sub-method.

Check to activate and select the positioning (normally just leave the left and right side selected).

Hardware fits perfectly

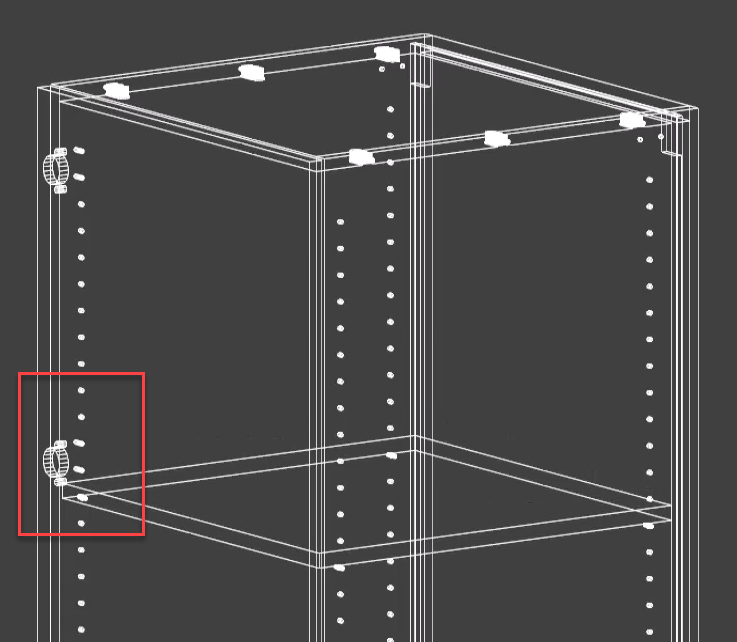

There is a vast quantity of hardware available that can be slotted and screwed into the 32mm cabinet system.

It’s then very easy to lock any hardware and horizontal separation onto the holes.

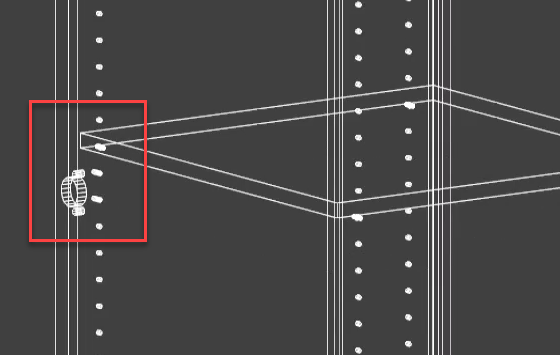

In the image below you can see the hinges align to the column of holes and the shelves are resting on the holes.

In PolyBoard, hardware like hinges has its own positioning rules. We can lock them into the 32mm configuration which also activates an anti-collision system.

Move a shelf and the hinge will adjust to fit, positioned as close to its own positioning rule as possible but within the confines of the 32mm system layout.

Here’s the same highlighted hinge moved below the shelf when the shelf was moved higher.

Dynamic manufacturing output

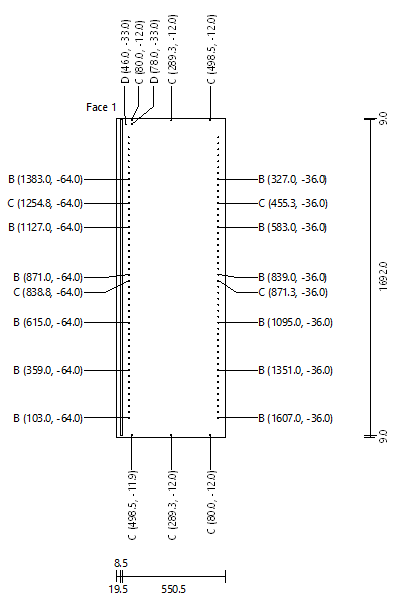

PolyBoard provides instant access to the manufacturing output, with all details of the 32mm system incorporated.

This includes a PDF workshop document with a cut list and plans of each part that detail the positioning of the holes.

CNC files also include full machining details.

Make any design changes, add new components or resize the dimensions of the carcass, and new holes will be added or removed automatically.

32mm system cabinets are a great way of standardising modular storage units.

We have more information on PolyBoard cabinet software here.

And don’t forget to look into OptiCut our sheet cutting optimization software, which is the perfect complement to PolyBoard.