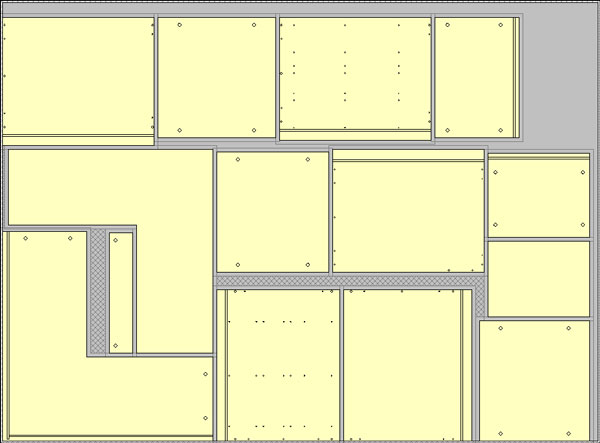

Minimise material waste with true shape nesting

Fully manufacture parts directly on your CNC machine

Interfaces with our PolyBoard furniture design software

OptiNest key features

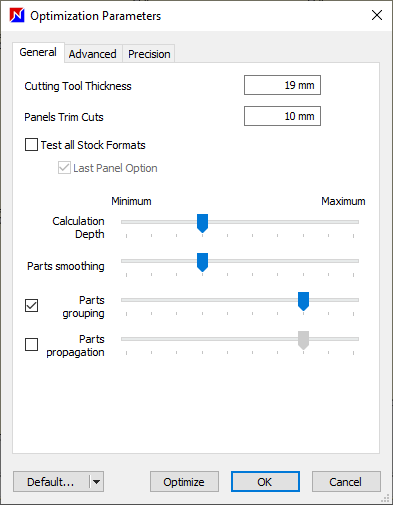

Optimise according to your own priorities

OptiNest's adaptable algorithms make it possible to adjust the optimisation to your specific needs.

If cutting very expensive material put the priority on minimising waste, if cutting cheaper materials on an expensive CNC optimise the machine cutting time. If you have a lot of parts to nest minimise the nesting calculation time.

This is what makes OptiNest truly industrial grade nesting.

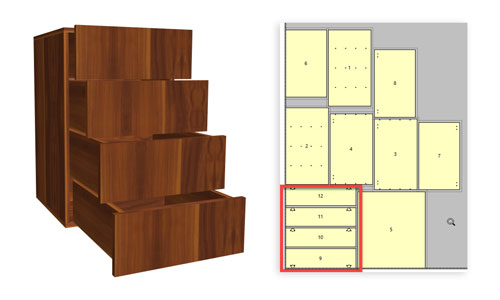

Grain management function

This feature works in combination with PolyBoard. In your cabinet design group a series of parts e.g. door façades, then apply continuous grain across them.

PolyBoard writes a post processor report including this grain identifier, for input to OptiNest so the parts are placed in sequence next to each other.

Another reason OptiNest is the ideal nesting software for woodworking.

Parts grouping function

Parts are paired to create 'virtual pieces', which in turn will be used as single parts during the optimisation process.

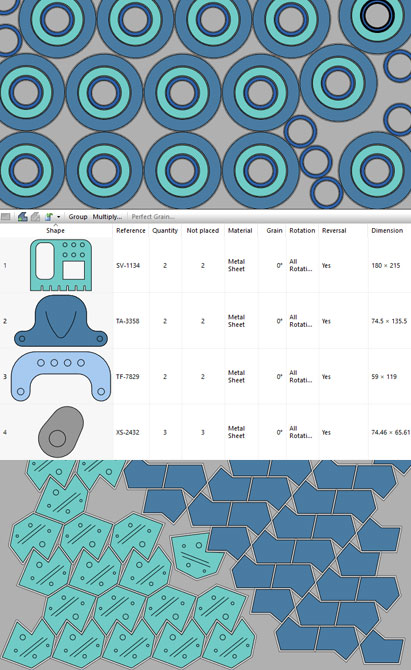

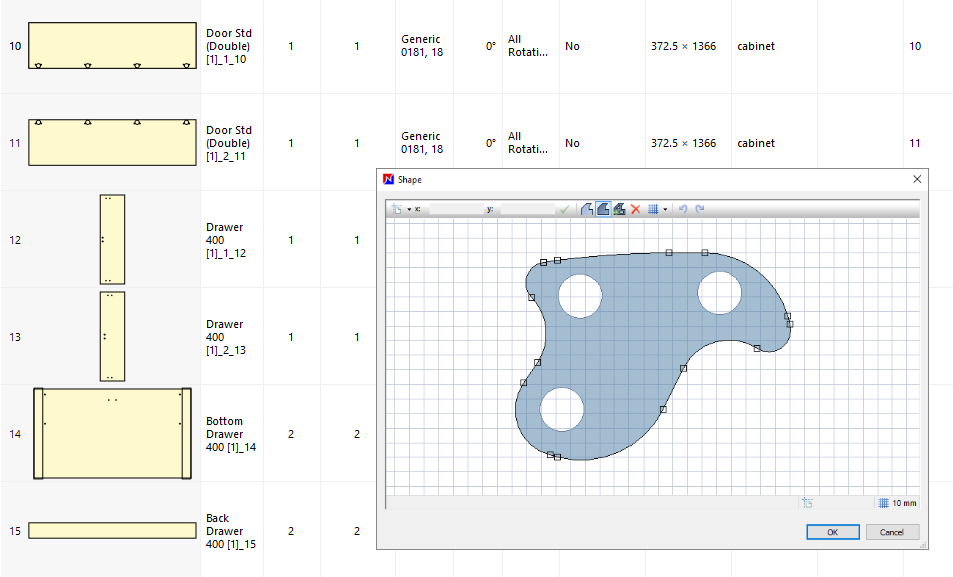

Drilled parts

OptiNest can manage drilled or bored parts. Holes are treated as a specific tooling type. The software also recovers the material freed by cut outs, and re-uses it to place smaller parts.

Rotations and reversals

Rotation and reversal parameters define the permitted part movements, rotations and flipping. Our nesting software accommodates 4 rotation levels and flipping.

Propagation mode

Propagation describes the placing method of a single part produced in large quantities, minimising the off cut rate.

As a general rule, the part is grouped with itself, then the grouping is propagated along 2 axes. The larger the panel size, the greater the level of optimisation you'll obtain.

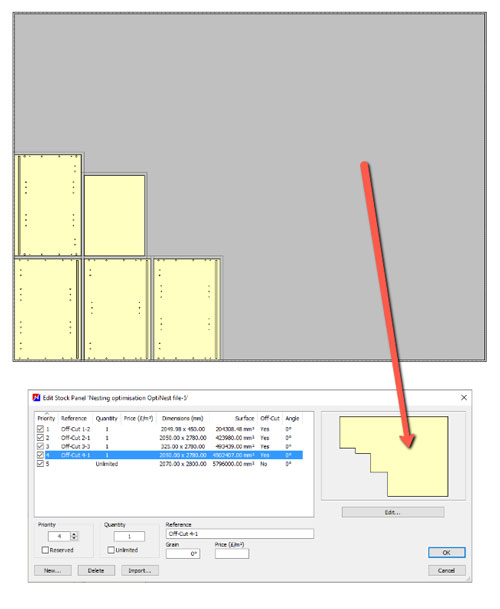

Automatic stock and off cuts management

As an alternative to setting unlimited panel stock levels, you can specify your existing stock levels for all materials and define your own usable off cut settings.

After each optimization, your stock will be depleted accordingly but you can also add back in those valuable off cuts for use in future projects.

Stop wasting time, money and effort

It's not only material savings you'll make with OptiNest.

Nesting optimisation will increase throughput, boost quality control as you create the right parts every single time, reduce programming time compared with your current method and reduce overheads as you minimise machine usage and wear.

At the end of the day, more cash in your pocket.

Nested manufacturing power

Parts import or direct entry

Parts can be imported from DXF files or drawn directly in OptiNest's graphic editor.

Parts can be drawn with any shape and cut out. To fully minimise waste, our nesting software will also use the cut outs to nest parts where possible.

OptiNest is a stand alone solution but woodworkers can benefit from seamless integration with our PolyBoard cabinet design software. Design in PolyBoard, all parts are automatically sent to OptiNest.

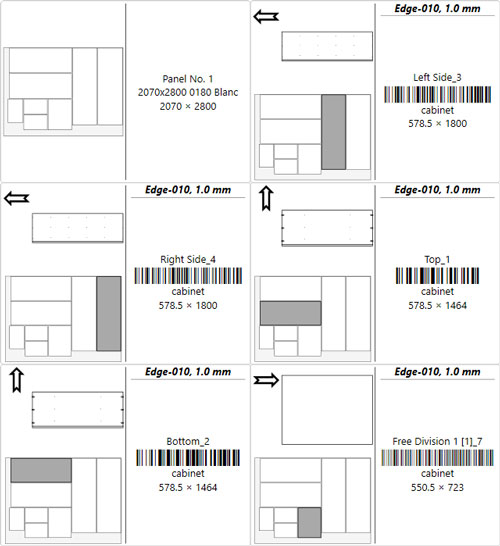

Nesting maps DXF export

The nesting maps created by OptiNest can be exported in DXF format, and then transferred to your CAD/CAM software and on to your CNC machine.

These DXF files include a series of layers. Each layer maps the machining operation for a specific tool. It is possible to link the layer names to your specific tools so they are automatically chosen. No need to manually chose the right tool each time.

All the data is included to cut your parts and machine them in a single manufacturing process. This is the key benefit of nested production and is perfect for custom projects.

Integration with all nesting CNCs

OptiNest outputs industry standard 2D DXF files with full cutting and machining details for every part.

DXF files are accepted by all CNC software which in turn generates the code to run your machine.

That's why we are happy to guarantee our nesting software will work with your CNC.

Double sided machining of parts

A nesting CNC is constrained to machining one side at a time. You can either flip whole panels that require machining on both faces, or perform those additional tooling operations by placing single parts on the machine again or on another machine.

In conjunction with PolyBoard, both solutions are efficiently managed by a powerful filtering system to separate the output as required.

Automatic label printing

OptiNest's customisable labels include barcode and touch screen functionality.

Labels are printed in the sequence the parts are nested for easy application.

Choose the information you need, data fields including but not limited to:

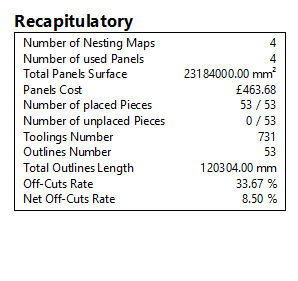

Material, cost and optimisation reporting

View and print a report detailing the results of your optimisation.

Metrics include total stock of material used, the material cost, off cut reuse statistics, and machining load for the job.

All measuring units, all currencies supported.

Watch your productivity and business grow

OptiNest is a key component of nesting CNC production, ideal for small and medium business working on custom projects.

I found this workflow amazingly user friendly and great to pass all the manufacturing information down through production with ease, the visual aspects of both PolyBoard and OptiNest meant spotting mistakes before they could even happen.

Dean Price

Tees Tech Joinery, PolyBoard + OptiNest + SCM CNCs

OptiNest Pro

Lifetime licence

Fully featured professional software for nested CNC manufacturing