- Home

- Help Centre

- OptiCut tutorials

- CNC saw integration

- OptiCut integration with your CNC saw

OptiCut integration with your CNC saw

OptiCut Pro PP includes a range of post processors to convert the cutting patterns into files compatible with CNC saws.

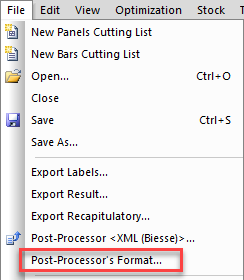

OptiCut’s post processors can be accessed from the Import/Export options window via the Tools menu, or go to File menu > Post processor’s format:

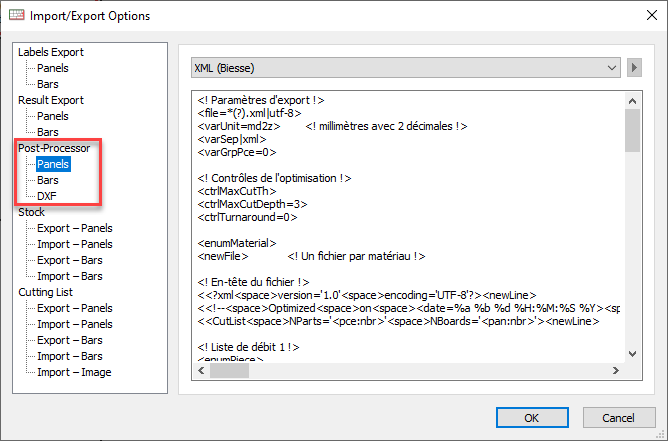

Select from:

- Panels

- Bars

- DXF – exporting the cutting patterns in a DXF shape

And then select the specific post processor, the XML (Biesse) panel post processor is shown below.

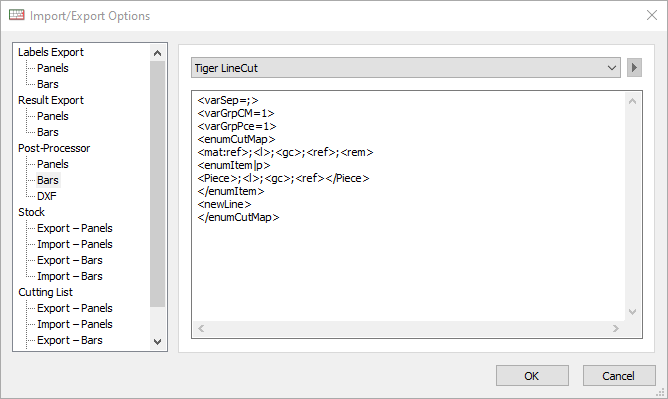

Here is the Tiger LineCut bars post processor, for use with TigerStop linear saws.

The post processor will normally work without any changes, but if required the code can be customised directly from this window. Please contact us for assistance.

Here is the full list of panel post processors:

- AC/AD

- AES Alpha

- Altendorf 1

- Altendorf 2

- Canigo

- Cassadei MC Editor

- Condal SMH366 V207

- CPOUT (Biesse, Giben)

- Demeyere

- DXF

- Geometric

- Homag VIC800S

- HPGL

- iLénia (Homag)

- iLénia 2 (Nimac)

- iLénia 3 (ACM)

- KDT

- Kvara Monolama

- Macmazza (FMM)

- Macmazza (PRO)

- Mayer PC5400 / PC6000

- Mayer PC7000

- Nanxing Machinery

- NPS400 (Homag, Casadei MX)

- Panhans 1

- Panhans 2

- Panhans 3

- PRV (Schelling)

- PTX (Homag, Giben) version 1.02

- PTX (Homag, Giben, Ayza Mizrak) version 1.08

- PTX (Homag, Giben, Ayza Mizrak) version 1.15

- PTX (SCM) version 1.14

- R41

- R41 / Microvellum

- SCM MaestroCut

- SCM Master

- SCM Master (Imperial Unit)

- SCM WinCut

- SCM WinCutPlus 1

- SCM WinCutPlus 2

- SCM Xilia Master / X1000

- Selco NC500

- Striebig

- Tai Chan Unik (PSX)

- TPA (XML)

- Turanlar

- XML (Biesse)

- XML 2 (Biesse)

This is the full list of bar post processors:

- BTL

- Default

- Elumatec (DGX)

- Elumatec (XML)

- FOM

- Mecal

- RazorGage

- Ruf (CSV)

- Salvador

- Stromab

- Tiger LineCut

Cannot find your CNC saw on this list?

Don’t worry, we are creating new post processors all the time.

Contact us if you’d like to discuss the possibility of setting up a post processor, or to confirm which post processor relates to your saw.

Please also note that some saws do not offer full CNC automation but can accept the output as a spreadsheet. Haffner Murat saws are one example of this set up.

Where this is the case, OptiCut can generate the optimization results as a spreadsheet to load into the saw.

Output the post processor files to run your saw

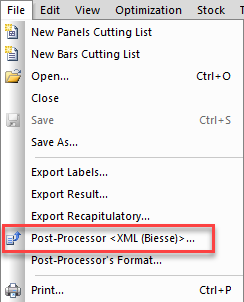

Select the Post processor icon to generate the files for your saw.

This command is also available from the File menu:

Test OptiCut’s post processor output

You can download the trial version of OptiCut and create an optimised cutting map, but it won’t include all the details to allow you to cut the parts. Below you can download a sample optimisation in full.

Sample cutting optimisation files

We’ve included a cutting map for both panel and profile/bar optimisations, along with part by part labels and files for your CNC saw.

Please consider a complementary screen sharing session with us if you would like to confirm the compatibility of a CNC saw with OptiCut. We can also create a new post processor for you if required.

Contact us to request a compatibility test

Additional settings for selected CNC saws

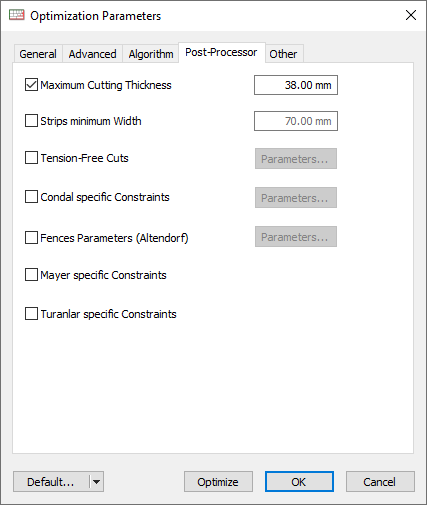

To access these, go to Optimization > Optimization parameters > Post processor:

Maximum cutting thickness

Linked to the thickness your saw can accommodate by stacking panels on top of each other.

Strips minimum width

Another machine dependent setting, the minimum width that the saw can accommodate and clamp correctly.

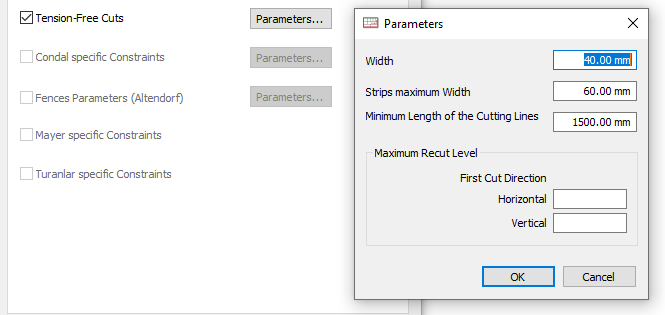

Tension free cuts

Tension can build up in long sections of material. If this is causing distortions in the cutting process, these settings can be used to limit the dimensions.

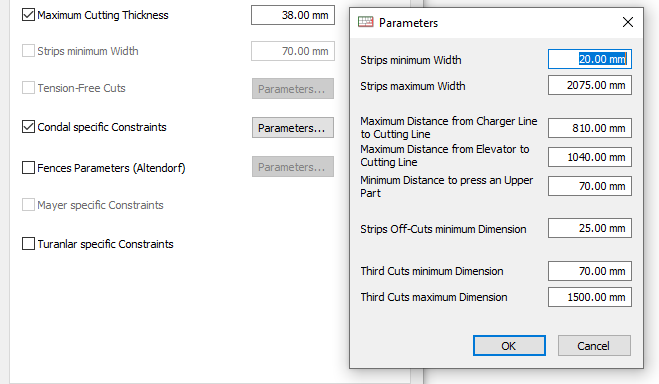

Condal specific constraints

Specific constraints required for Condal saws.

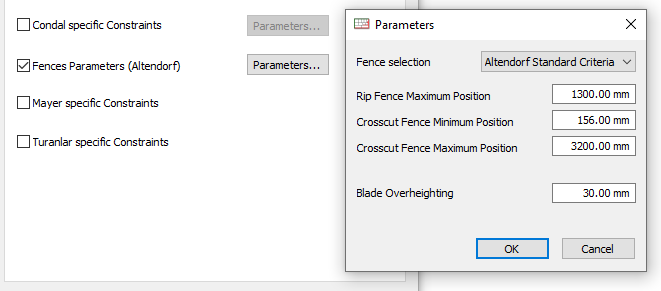

Fences parameters (Altendorf)

Management of Altendorf specific settings related to the priority between the rip fence and the crosscut fence depending on the part size.

Please also note that there are two different Altendorf post processors. Altendorf 1 relates to older generations of the Altendorf controller, normally, you would be using Altendorf 2.

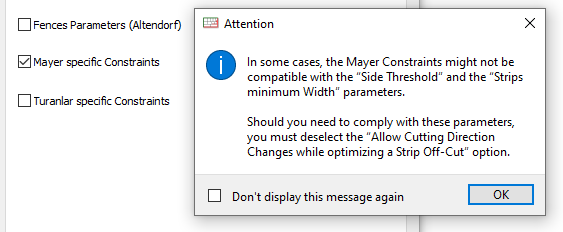

Mayer specific constraints

Instructions for configuring OptiCut with Mayer saws.

Turanlar specific constraints

Built-in configuration for Turanlar saws.

Further saw specific information

We have created some additional resources for specific brands of CNC saws. These can be accessed here: