Turnkey CNC routers for the woodwork industry

Specialist wood CNC machines with integrated software for seamless design and manufacturing

PolyBoard, StairDesigner, OptiNest and VCarve Pro: choose the right mix for your production needs

What makes this set up one of a kind

A unique turnkey solution

The only truly complete design to manufacturing solution on the market

Designed for woodworkers

From router specifications to the software, hardware libraries and technical expertise, everything is configured for the woodwork industry

Stunning value

Nobody else gets close to the prices we offer at this level of performance

All too often we hear from companies that are struggling to run their design software and CNC machines together effectively.

In response, we have partnered with a select group of local CNC suppliers to develop a turn key configuration which includes Automatic Tool Changer routers fully integrated with PolyBoard Pro PP. We also offer a range of additional configurations to meet your requirements.

Example ATC configuration

ATC CNCs are the perfect blend of affordability and quality, complete with market leading parts. PolyBoard and StairDesigner integrate perfectly with VCarve to output the code needed to run the CNC.

Backed up by excellent training and support, this software/CNC combination gives you access to an incredibly fast and efficient design and production process...at unbeatable prices.

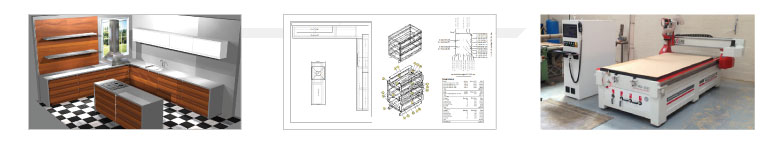

The beauty of this specialist woodwork configuration

Our turnkey CNC router solutions have everything you need to get from the initial design to finished product as fast as possible and without errors.

A unique and total solution for the woodwork industry.

Quick and precise design in PolyBoard, or StairDesigner

Machining for your hardware automatically applied in PolyBoard. Plus 3D presentations for clients and automatic costings to produce quotes fast.

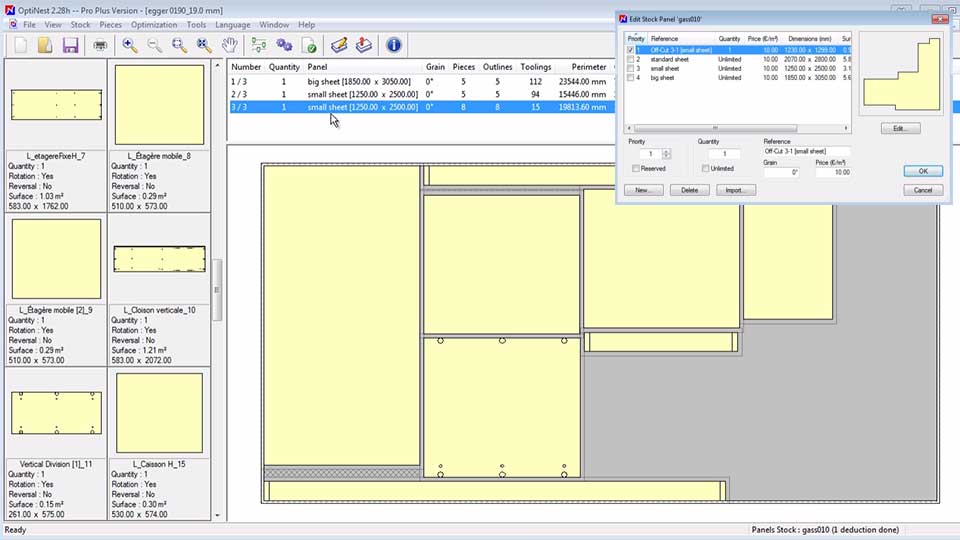

Seamless transfer to OptiNest saves time and money

PolyBoard automatically transfers the design to OptiNest for production of optimised nesting maps.

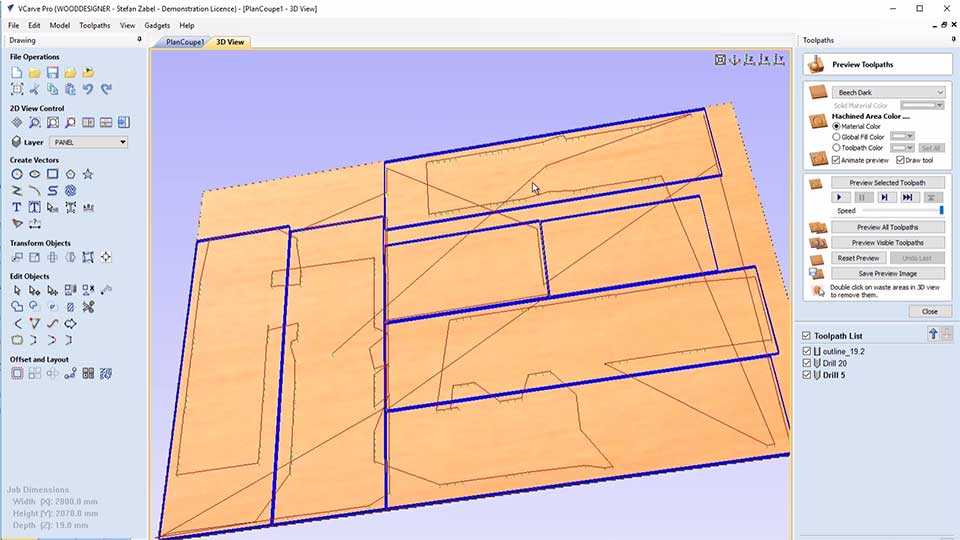

Pre-configured VCarve templates

VCarve then outputs the machine code to run your CNC in seconds

A tool pack created specifically for woodworkers

All toolings are set up in PolyBoard and VCarve manufacture ready.

PolyBoard and StairDesigner

Close the deal

One click 2D/3D presentations and detailed costs for immediate quotations.

Speed

Much faster than drawing by hand or CAD, with automatic and instant CNC output.

Cut out production errors

Click of a mouse editing updates all your CNC output in real time.

Powerful but simple to use

Trusted by 1000s of companies around the world…small to medium workshops to industrial manufacturers.

CNC ATC routers

Fast and accurate

Auto tool changer with height sensor supporting 8 tool paths.

Market leading components

Italian HSD spindle, Japenese Yaskawa driver system, Hiwin rails.

Many more must have features

Vacuum pump with zoning system, dust extraction, helical rack and pinion technology and T-slot table.

Excellent warranty, training and support

3 year warranty, comprehensive training following installation, lifetime support.

Sample specifications of our CNC machines

Our configuration includes the CNC machine, PolyBoard Pro PP and/or StairDesigner, OptiNest Pro, VCarve Pro, install, set up and full training. The machine specification remains the same across the range, the working area is the key difference.

ATC 1325

1300 x 2500 mm

ATC 1530

1500 x 3000 mm

ATC 2030

2000 x 3000 mm

ATC 2040

2000 x 4000 mm

Warranty and support details

Your CNC router comes with a warranty of 3 years on parts, 1 year for labour. Also included in the price is installation, delivery and training on site. Lifetime technical support is available via email and phone.

A comprehensive training and support package is included for our PolyBoard, StairDesigner and OptiNest software solutions.

* optional, depending on your production goals

Choosing the working area of your machine

ATC 1325

The ATC 1325 allows you to use a complete standard size small sheet of 2.50 x 1.23m. So sheet sizes are small and easy to load, unload and flip.

The 1325 is also one of our most affordable options and is small enough to fit in most workshops.

ATC 1530

Accommodate the same smaller standard sheet size as the 1325, plus half of a full size standard sheet of 2.80 x 2.07m. This keeps panel sizes down and easy to handle.

Allows you to cut longer parts when necessary, so well suited to building stairs. You can cut almost any stringboard as a single part, or in two parts assembled afterwards with a puzzle joint or similar.

You can also machine furniture parts longer than 2.50m, useful for projects where you have high ceilings and need furniture to match.

ATC 2030

The ATC 2030 allows you to cut and machine larger parts, providing a better optimisation of material and saving time as less manual intervention is required.

ATC 2040

The ATC 2040 will manage very large parts for ultimate flexibility e.g. stair strings up to 4m, and larger furniture parts.

Contact us for more details on our CNC turn key offers.