- Home

- Help Centre

- OptiCut tutorials

- Extended

- Stock and off-cut management

Stock and off-cut management

In the Essentials section, we’ve seen how to set up a stock of panels and bars in OptiCut.

The stock quantities can be set to unlimited. However, if you set actual stock levels, following an optimization it’s possible to reduce the stock of panels and bars by the number of used parts.

In addition, it’s possible to add off-cuts back into your stock for use in future optimizations.

Stock management in OptiCut is a simple way to limit material waste further and fully control stock levels in the workshop.

Both stock and off-cuts can be managed or just one of these elements.

Recoverable off-cut settings

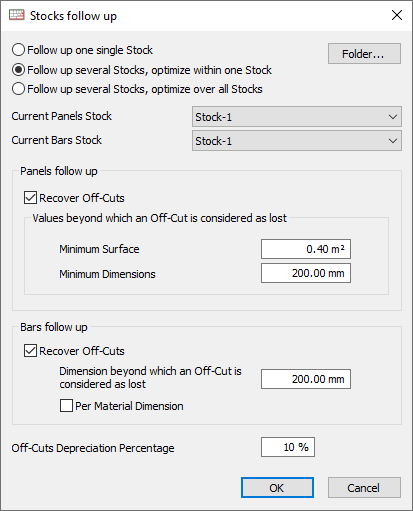

Go to Tools menu > Stocks follow up to define which off-cuts can be reused.

Here you can set a minimum surface area and dimensions below which off-cuts will not be returned to the stock.

The top settings allow you to optimize and add off-cuts into single or multiple groups of stock.

The off-cut depreciation percentage can be used to reduce the material price as shown in the optimization results.

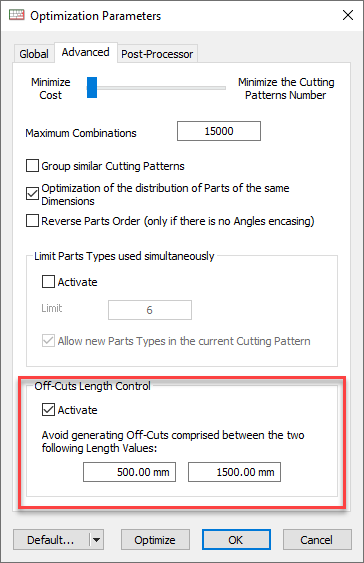

An additional setting is available for bar off-cuts, and can be found in optimization parameters > Advanced:

This excludes the creation of off-cuts when the length lies between the minimum and maximum values.

The result will be increased re-usable off-cuts but with an increased number of required bars.

Off-cut display

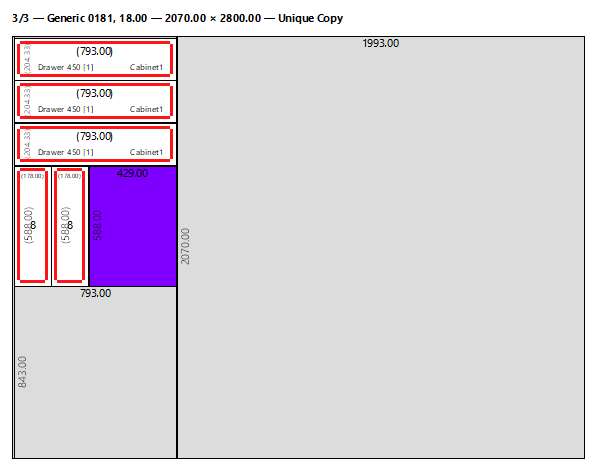

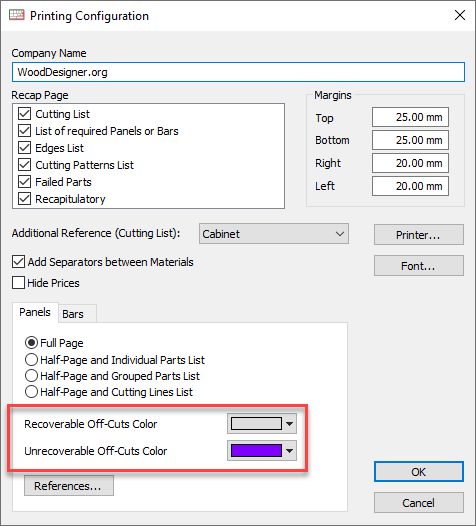

The cutting pattern print out can show whether the off-cut is recoverable or not.

The colours are set in the File menu > Print setup window.

Updating stock levels

Following an optimization, use the Deduct command to update stock levels.

This command is also available from the Stock menu.

This does two things:

- Reduces panel and bar stock levels (unless stock quantity is unlimited)

- Adds recoverable off-cuts into the stock

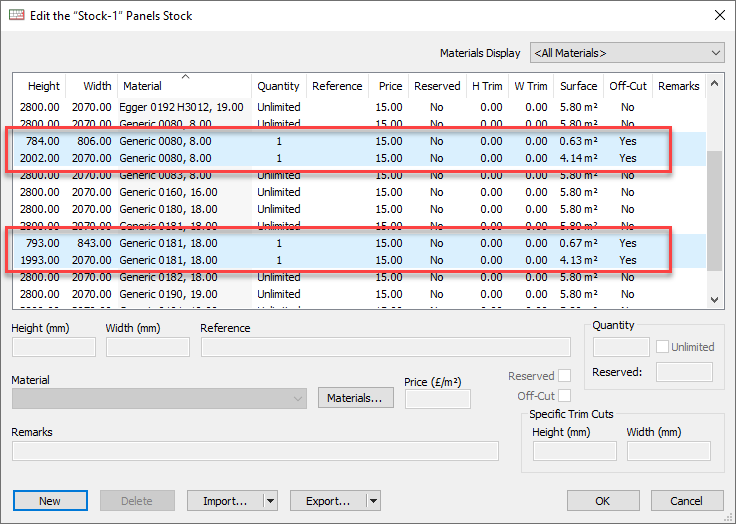

The stock list below shows the added off-cuts.

The next optimization will place the parts on the original stock and these off-cuts.