- Home

- Help Centre

- OptiNest tutorials

- Extended

- Stock and off-cut management

Stock and off-cut management

We covered how to set up stock in the Essentials section:

The panel quantity can be set to unlimited. It’s also possible to define true stock levels. After an optimization, the stock quantity will be reduced.

Additionally we can define reusable off-cuts and add those back in to the panel stock for use in future optimizations.

OptiNest’s stock management features are simple to use but offer a very easy way to know when it’s time to order more panels, minimise material waste and keep costs down.

Choose whether to manage panel stock levels and reintegrate off-cuts, or just use one of these features.

Configure recoverable off-cuts

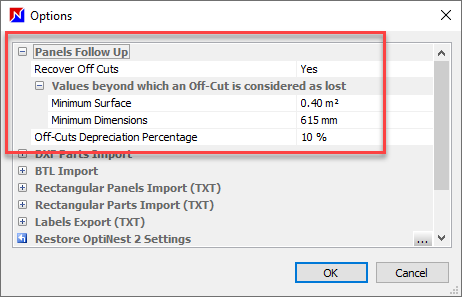

Go to Tools > Options to define your recoverable off-cuts.

When Recover off-cuts is set to Yes, configure the parameters to define:

- The minimum surface area of recoverable off-cuts

- The minimum dimensions

- A depreciation percentage: this reduces the optimization result material price

Off-cut colour

As a reminder, the off-cut colour can be set in Tools > Preferences.

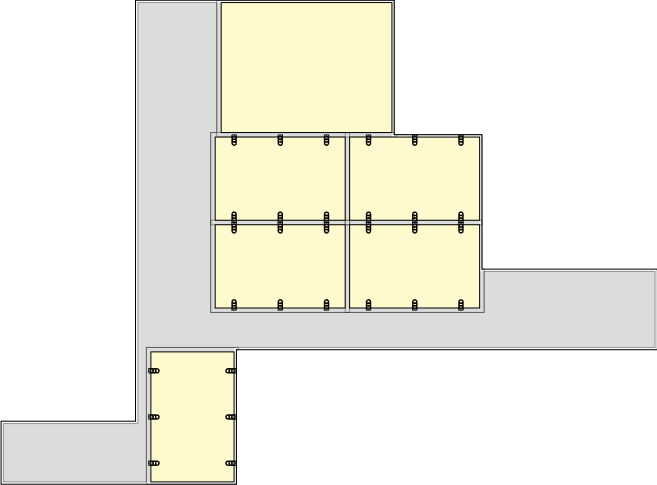

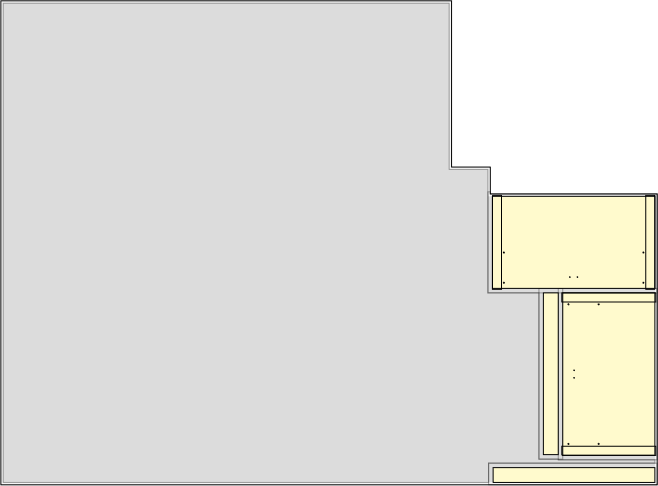

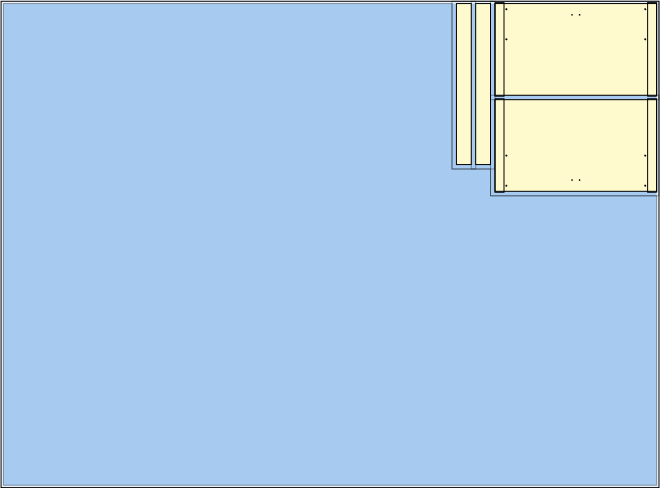

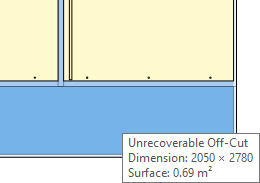

Whichever colour is chosen, recoverable off-cuts are lighter in colour, unrecoverable off-cuts are darker.

To determine if an off-cut is recoverable or not, you can also hover over it with the cursor.

Updating stock levels

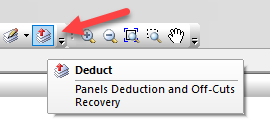

Once an optimization is complete, select the Deduct command to update stock levels.

Alternatively, go to the Stock menu > Deduct.

This operation results in the following:

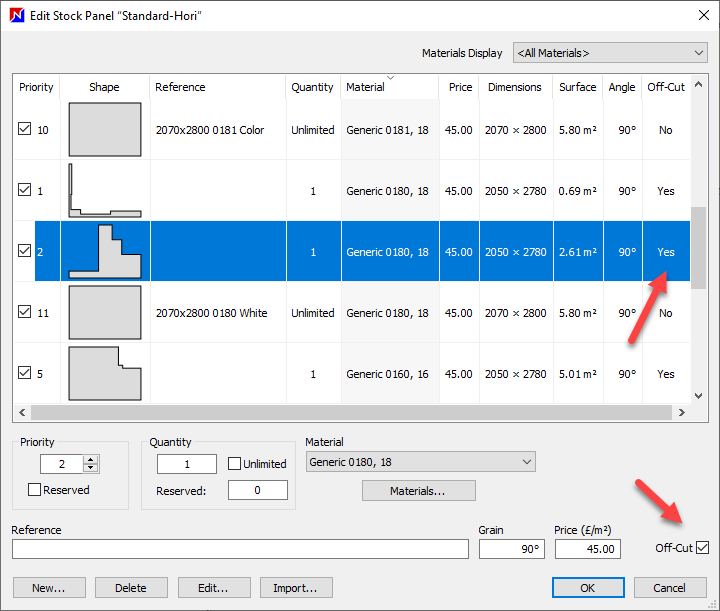

- The panel stock is reduced by an amount equal to all panels used in the optimization (assumes stock is not unlimited)

- Recoverable off-cuts are added to the panel stock

The stock list below shows off-cuts added to the stock, an off-cut parameter also highlights them as off-cuts.

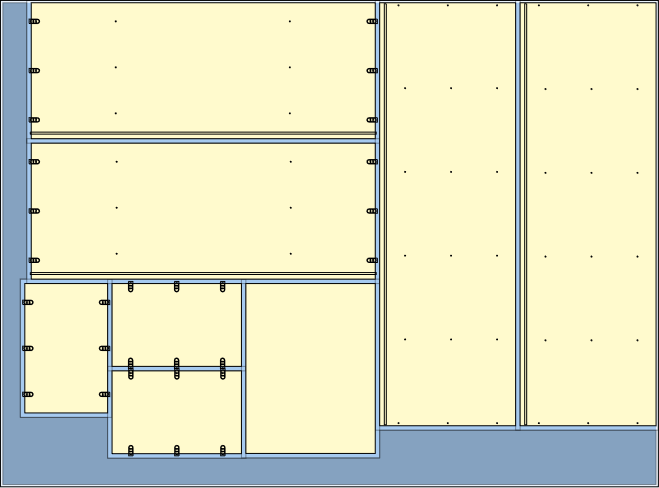

Future optimizations will nest the parts on all available panels, including the off-cuts, as shown below: