Wood Designer forum

Gardner Stair Design|Page 2|Forum|WOOD DESIGNER

October 4, 2012

Hi Ryan,

Thanks for this information, before I process can you just check the sizes on this plan:

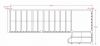

My main concern would be the total length of the back flight which is 3600 from the out side of the right hand string to the last nosing, not including any landing step, is this correct?

Stringers are extended 70mm beyond the last nosing and this step is 150mm wide.

If all is OK I can send the working documents.

All the best,

Ness

October 4, 2012

Hi Ryan,

One last point before I process the manufacturing files.

Can you tell me if you are going to cut and machine the parts by hand or with a CNC?

If you are using CNC, do you need the PDF full size templates ?

DXF files can be set up to have specific layer names to help with CNC tool pathing, do you need this to be set up?

All the best,

Ness

Thanks Ness,

That looks great. Lets go with this. I think there will be a little width and length adjustments to make before I do the final build however I can change these manually.

If you do output cad files I can also modify these myself.

Thanks for you assistance. Hopefully I can make it look as good as the design.

October 4, 2012

Hi Ryan,

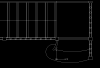

In this case I would create a start with an opening only to the left, a bit like this:

this is just a mock up as StairDesigner doesn’t let you shape the steps. In reality I would export the StairDesigner DXF file to CAD and adjust the details like this:

In fact in IMHO the actual detailing of the first steps can be set up in CAD to your own tastes. On the first 2 steps goings and step shapes can be tweaked aesthetically without worrying to much about stair rules.

Note that although I do this CAD you can also just print a full size drawing and do it by hand!

If this design suits you I can send you the files and you can work from there.

All the best,

Ness

Hi Ness,

I am happy with the bull nose, however with the location and setup we have we will need to keep the right hand handrail and banister. There is a step down in the floor immediately to the right of this flight.

Other than that I have no problems with what you have done

October 4, 2012

Hi Ryan,

Sorry I’ve taken a bit of time to reply, I’m very busy these last days and I actually wanted to take a bit of time to get into your project.

Although I think that your stair will work structurally I wouldn’t personally build the starting steps like this.

To make a more elegant start there are several options the simplest would be to make a couple of bull nosed steps like this:

This is less work than building a curved stringer, but IMHO gives a more harmonious result.

The tech details would require a bit of drafting in Draftsight.

Other options are possible but depend on the time you want to spend.

What do you think?

All the best,

Ness

August 7, 2014

Hi Ryan ,

sorry . File attached now

regards

Michel

Thanks Michel,

You don’t appear to have attached any files. My plan is just to use pine and paint it white for the stringers and handrails. The stairs will be carpeted and it has been suggested that I just use Chipboard, but I was thinking of going pine or ply to ensure they last.

The only other thought was to perhaps have a hard wood outer stringer for looks. The curved stringer I will possibly make with ply by cutting the back of it. Or I’ll just make it straight.

1 Guest(s)