- Home

- Help Centre

- PolyBoard tutorials

- CNC integration

- Enhancing CNC workflow with multiple post processors

Enhancing CNC workflow with multiple post processors

PolyBoard’s multiple post processor feature empowers users with expanded capabilities for managing data sent to CNC machines.

It offers a diverse array of options for handling data across multiple CNC machines, with the added benefit of conditional validation based on tooling types, panel characteristics, and dimensions.

This article explores several key functionalities of this feature.

PolyBoard’s Quick Design libraries include two types of multiple post processors.

Excluding tooling types

Horizontal tooling isn’t typically involved in nesting manufacturing.

However, there may be instances where horizontal tooling is applied using traditional methods like lamellos, dowels, or cams.

The multiple post processor feature provides a filtering mechanism to prevent these horizontal toolings from being sent to the nesting CNC machine.

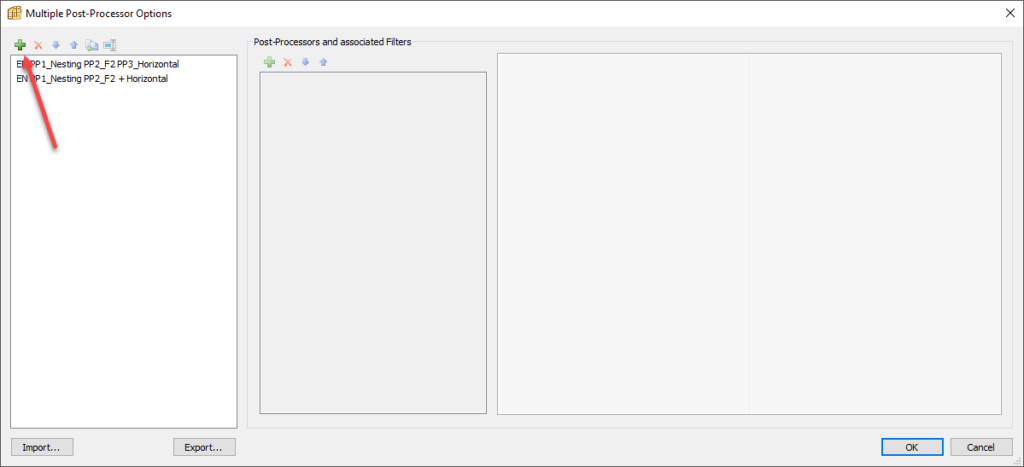

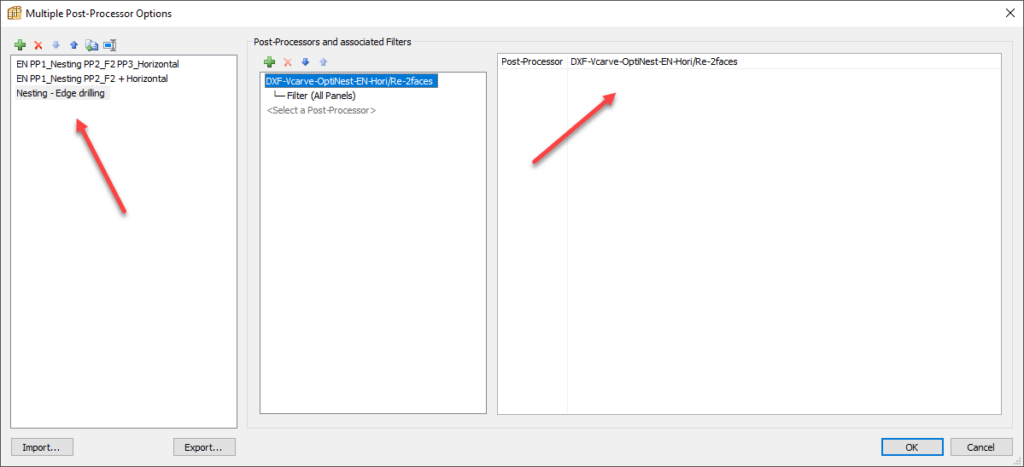

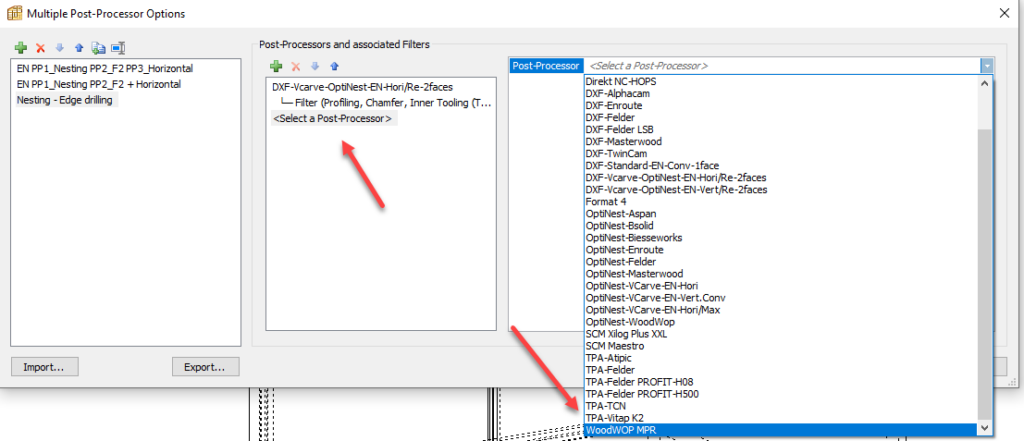

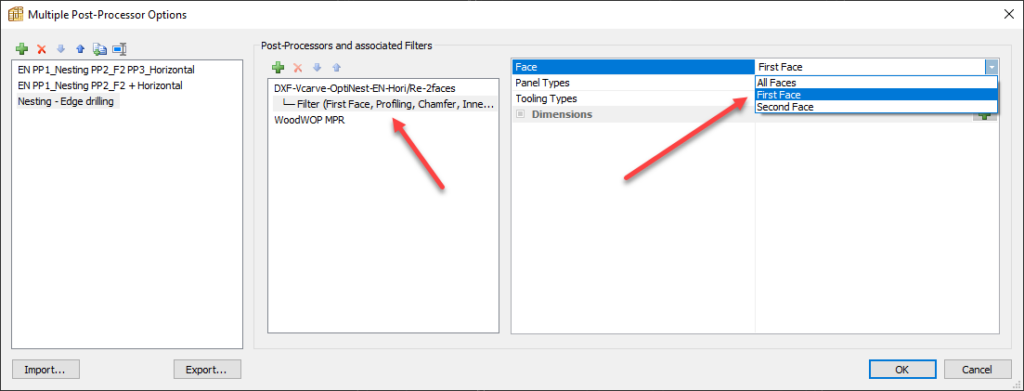

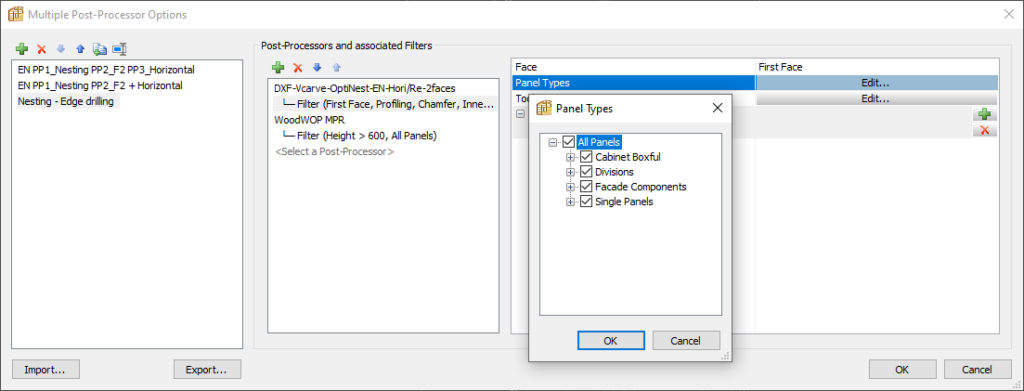

To set up this configuration, go to the File menu > Multiple post processor options.

Create a new multiple post processor by clicking the + sign.

Assign a name and select the appropriate post processor, for example the DXF post processor.

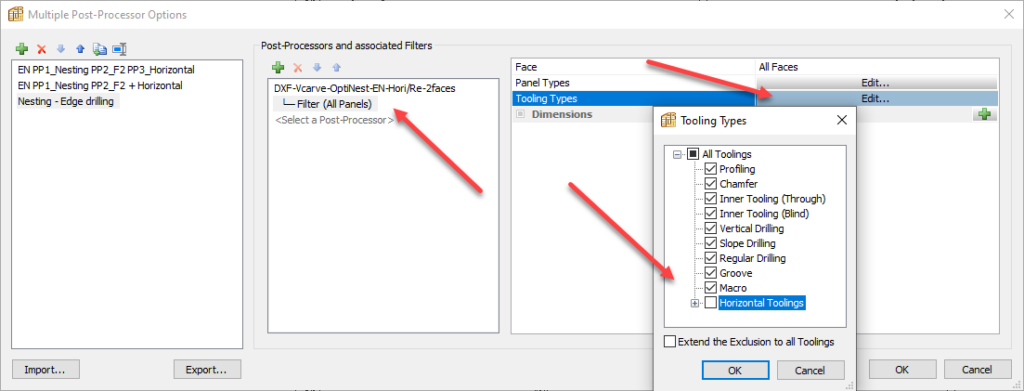

Utilise the Filter section to edit Tooling types and deselect Horizontal toolings.

Confirm these changes.

The resulting post processor can then be employed to export DXF files free of horizontal toolings.

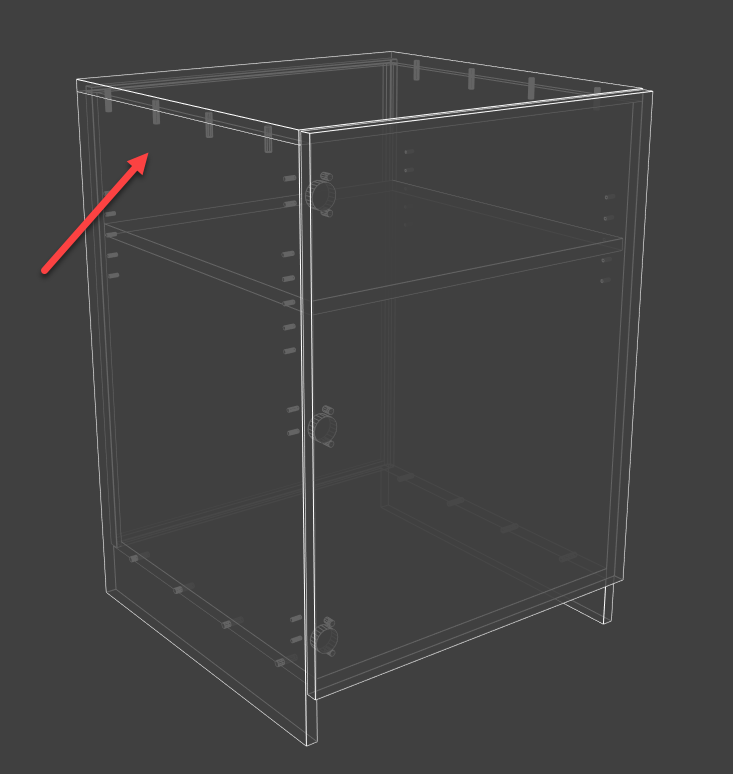

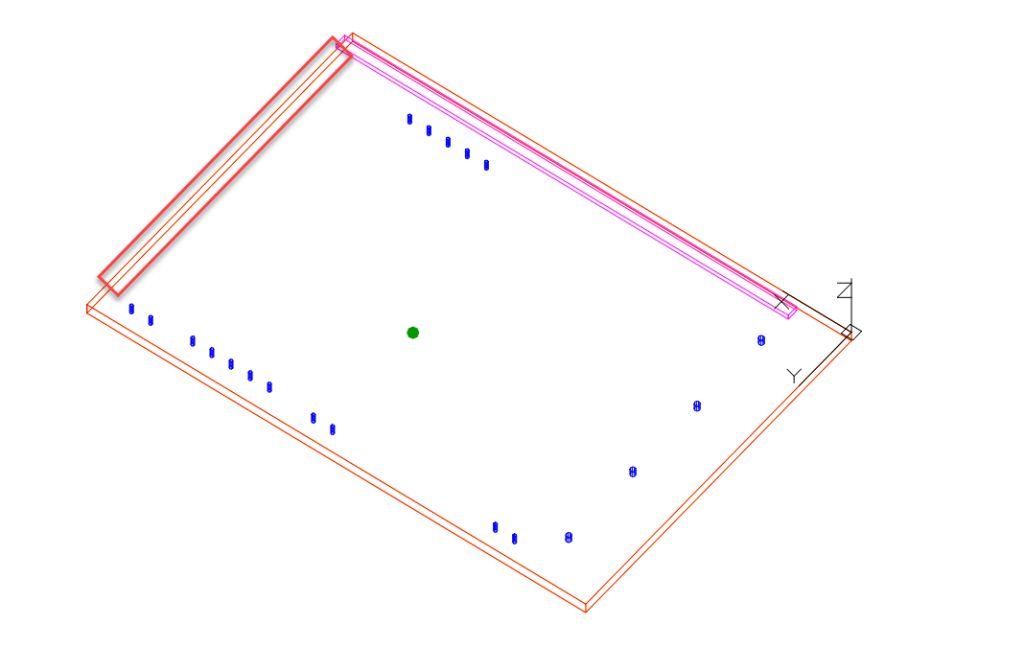

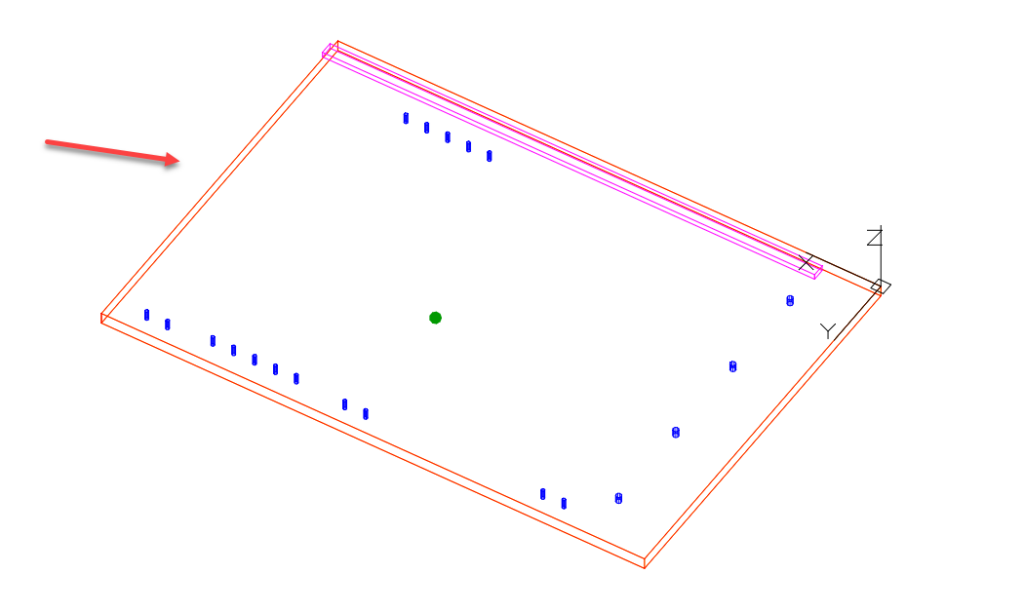

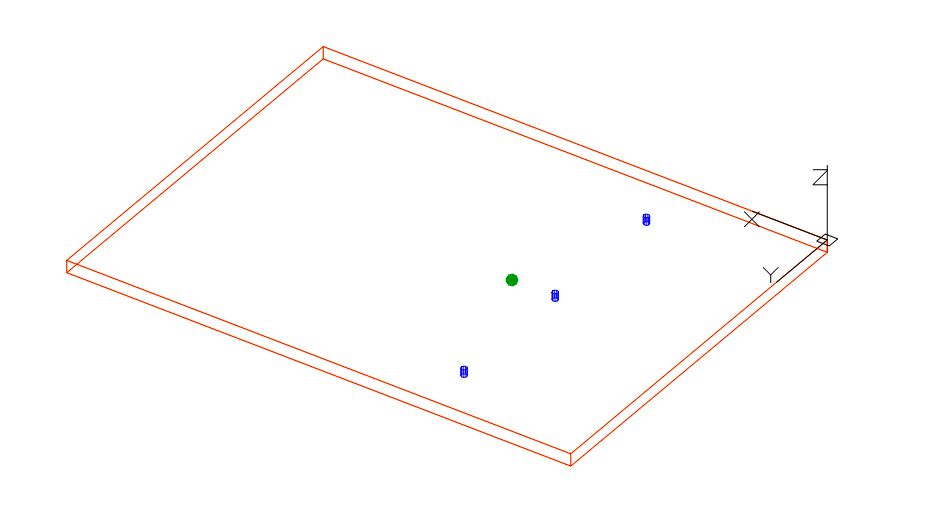

Below is a visual representation of a cabinet displaying horizontal toolings on the left side (edge tooling).

Subsequent exports will show the removal of the horizontal tooling, ensuring correct CNC machining.

In the PolyBoard manufacturing documents, the horizontal toolings are still included for manual application.

Routing specific tooling types to a secondary CNC

Expanding on the previous example, the multiple post processor feature enables the routing of specific tooling types to a secondary CNC machine.

Let’s return to the previously configured post processor in the multiple post processor options.

Now select a secondary post processor, for example woodWOP, for which we’ll associate with specific tooling requirements.

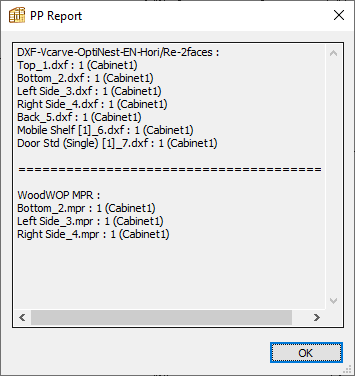

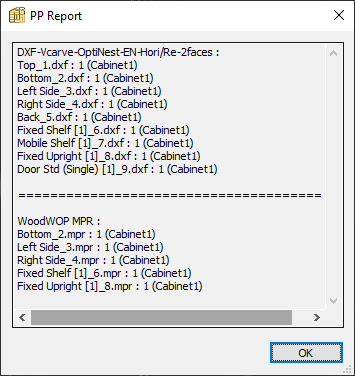

PolyBoard creates separate folders for DXF and MPR files upon output, streamlining workflow efficiency.

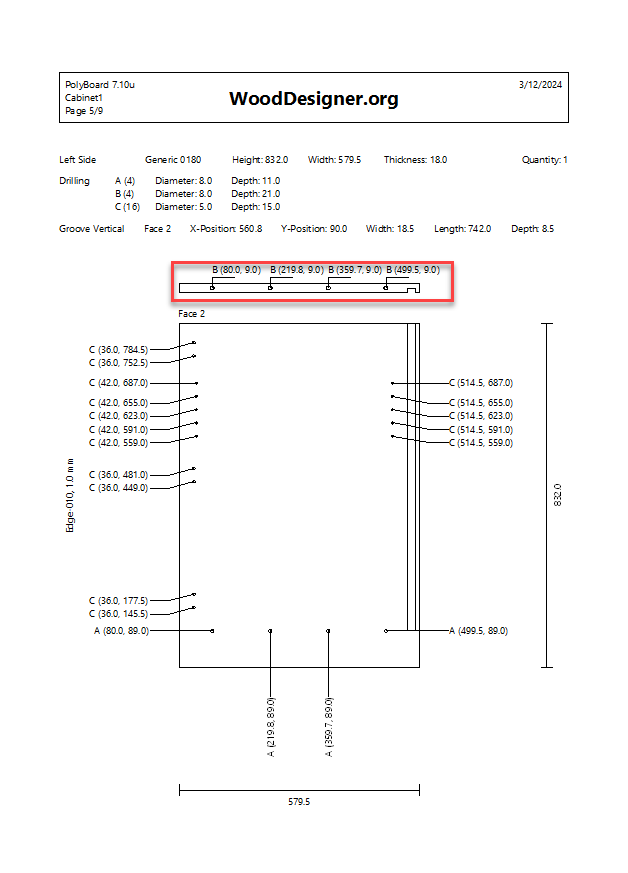

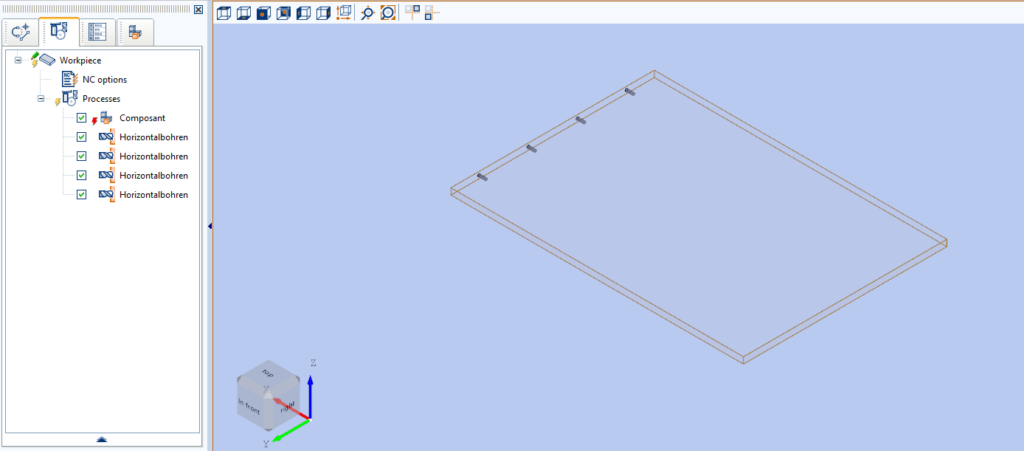

Here is the DXF file for the left side view, where the horizontal toolings have been excluded.

The view of the left side sent to the woodWOP post processor only includes the horizontal toolings in the generated MPR file.

Optimizing two face machining

In this scenario, the first face toolings, excluding the horizontal ones, are processed on the nesting CNC, while the second face toolings along with the horizontal ones, are directed to the second CNC.

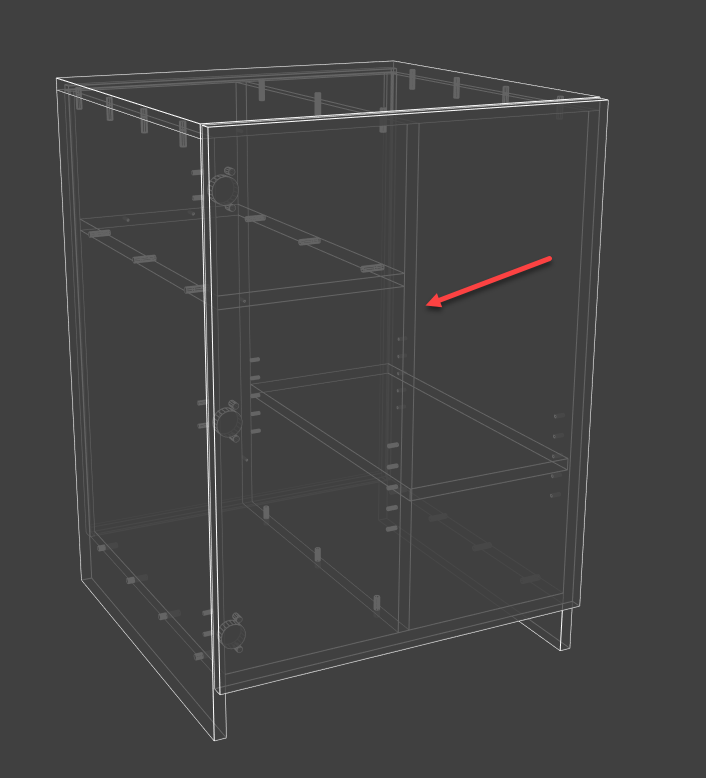

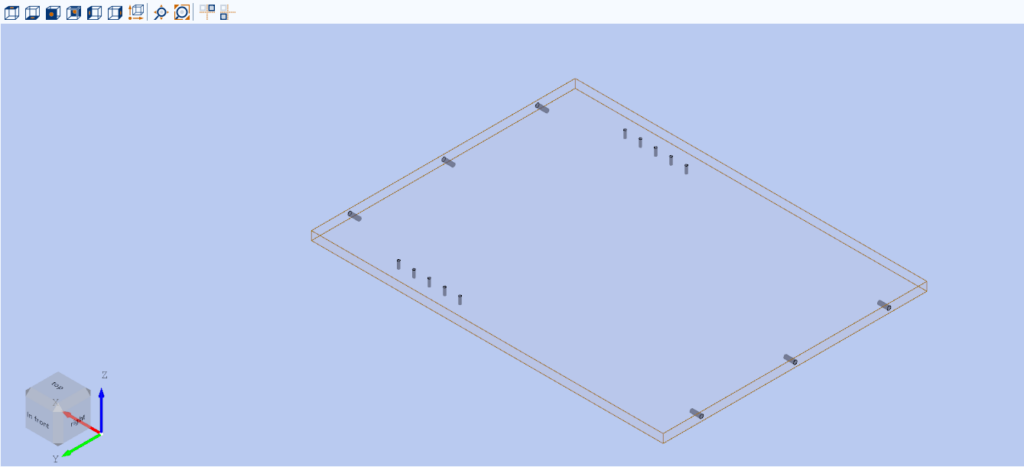

We’ve incorporated an upright into our cabinet design featuring a fixed shelf on one side and a mobile shelf on the other.

This configuration results in toolings on both sides of the upright as well as horizontal toolings.

Now we’ll revisit the multiple post processor settings and adjust the filtering to process only the first face toolings.

The outcome now will be that all toolings on the first face, except for the horizontal ones, will be sent to the nesting CNC machine. Toolings on the second face, along with the horizontal ones, will be directed to the second CNC machine.

PolyBoard generates two output folders, each designated for a specific post processor.

The visual representation of the DXF file of the upright shows the first face toolings.

Here is the visual representation of the second face toolings + horizontal toolings sent to the second post processor.

Additional selection criteria, such as panel type or size, can be applied to further refine the machining process.

To consider a specific application, certain components such as fillers, plinths, or upper strips may need to be assigned oversized dimensions, necessitating a tailored post processor setting during export. By applying this filter, these components can be isolated and processed using a customised post processor to ensure accurate output.

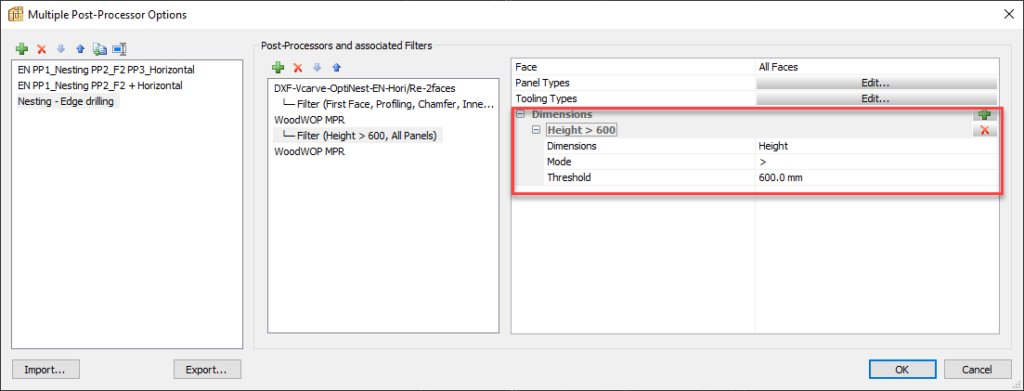

The last option is to select panels according to size.

In the example below, panels exceeding 600 mm will be processed, while those below this threshold will be excluded or passed on to the next post processor.

Note that the height and width are defined by the post processor orientation output, not exclusively by the cutting list orientation.

In summary, PolyBoard’s multiple post processor functionality offers a comprehensive solution for optimising CNC workflows and streamlining production.