Wood Designer forum

Hello from Acastrian York|Forum|WOOD DESIGNER

October 4, 2012

Hi Ed,

Your problem is in the DXF post processor set up.

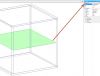

By default the groove parameters are set up for a saw cut groove and the position of the cut is calculated according to the diameter of the blade:

The start and end points of the actual cuts can also be set back (recess) or forwards (overlap).

If you are using a milling bit the groove parameters should be set up as follows:

In this case I’ve set up for a 7 or 8mm diameter bit.

The blade diameter is set to 0 because we are not using a blade.

The “Recess of non through grooves” is set to -4 so that the actual 8mm router bit will over cut 4mm and the Through groove overlap set to 4mm for the same reason.

Theses parameters will write a dxf files like this:

Hope this is helpful.

All the best,

Ness

Hi Ness,

A Happy New Year to you – Polyboard is still proving a God-Send!

A quick question. It may be a bug in the software or I may be doing something wrong. I’ve recently made a wall-hanging cabinet that needs an 18mm void behind the back for wall hanging brackets to fit. To that end I went for a back grooved into the top/bottom/sides; set in to the unit by 18mm.

The problem I have is with the sides. The .dxf export seems to stop the grooves short of the ends of the panels, contrary to what Polyboard is showing in the design. The result is that when the unit is assembled the grooves for the back to sit into (in the sides and top/bottom) don’t overlap. The top and bottom pieces are 19mm thick, and are overpassing. The groove for the side panels finish at 19mm from the ends, as opposed to being closer to the end to form an overlap.

I’ve attached the file as well as the .dxfs that were created. Could you take a look? Does this make sense?

Kind Regards,

Ed

October 4, 2012

Hi Ed,

The nicety and a few others will be available in v6 .

Thanks again for posting.

Keep us updated on future projects.

all the best,

Ness

October 4, 2012

Hi Ed,

Thanks for the feed back and the photos, it’s much appreciated.

For the shelf types, you can rename the actual nil panel part “Hanging Rail” so that it appears in the cutting list as such:

But in Polyboard v5, the part type “shelf 4” can’t be renamed .

We are working on version 6 where types can be created and named as wanted.

We are hoping to get v6 out at the end of 2015 or beginning of 2016.

All the best,

Ness

November 8, 2013

Hi Ed,

Thanks for the feedback and photo. Really glad to hear you’re successfully bedding Polyboard into your workflow.

Ness will get back to you on that shelf renaming issue to see if it’s possible to change or not.

All the best,

Stefan

Hi Ness and Co.

Firstly, just a quick question. I have set up PB to put in screw holes for wardrobe hanging rail socket. I’ve set up “Shelf 3” in the shelves list to be a Nil panel, that when inserted into the model is fitted to the sides/uprights using a drilling pattern that fits the wardrobe rail sockets I use. Very handy! How can I rename “Shelf 3” to something like “Wardrobe Rail”?

Secondly, we’re at the end of a very busy week where our first 2 PB designed and manufactured projects were installed. A few lessons learned (not the problem of the software – definitely the operator!) but all in all a tremendous success. The last installation (photo included) is not too ambitious, but worked a treat – thanks! It has saved us a huge amount of time and the accuracy is superb.

October 4, 2012

Hi Ed,

Nice to hear from you and know that everything is working well.

The Xilog PLus XXL post processor should appear when you go to “File>Post Processor Options” and “File > Post Processor Export”.

The Options will enable you to set up the Post Pro to the specific configuration of your suppliers machine as defined in the DEF file he wants to send you.

Once the Xilog post pro set up you can export all the parts as XXL files that can be read directly by a SCM machine.

This means that your supplier doesn’t have to set up the tool paths on a DXF file that you send him.

He just sends your file directly to his machine.

Once set up correctly production should be seamless, faster and smoother for your supplier.

The set up is done in the Options dialogue box and is quite straight forward for someon who knows the CNC parameters.

If Xilog doesn’t appear in the PP lists you might have erased it by error.

In this case use the Import button in the Post Processor Options to load the file below.

There are series of XXL setups that you can try and tweak.

Hope this is helpful.

All the best,

Ness

1 Guest(s)