Wood Designer forum

Introduction of Christopher Pare|Page 9|Forum|WOOD DESIGNER

October 4, 2012

Hi Christopher,

Sorry I posted the wrong file.

I’ve attached the project file again with the drawer assembly details and mortise and tenons for the frames.

You seem to have a good amount of equipment so with a bit of patience you should have everything you need.

I’ve set the drawers up with 1/2 gap for the runners and a tongue and groove way I would do them have a look and tell me if this is OK for you.

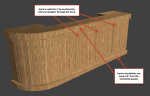

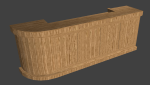

Here’s a quick screen capture to illustrate the panel divisions and the backs set back 1/8″, I’ve also set the plinths back to give the same effect.

A couple of question/suggestions for the lost space in the end sections:

If you want a curved backed drawer in the end Polyboard wont draw the inner parts as a drawer but it has to be set up as a separate cabinet. I would suggest that it be simply triangular and not curved.

This project will go together well using biscuits .

If you’re OK with this we can add the hardware and you should be set to go.

All the best,

Ness

Hi Ness!

Thank you for reviewing my project and providing your invaluable input. But there seems to be a problem as the file that you sent back only includes the center section of my Home Bar. This means that I am unable to follow your feedback as provided…

For the frames and panels, I want to ensure that the quality is very strong… That is why I was going with the 1/2″ panels.

In assembling the door and drawer frames, I was thinking of going with Mortise and Tenon option.

As to the equipment we have, it is as follows:

– 10″ Table Saw

– 12″ Sliding Compound Miter Saw

– Router Table

– Planer

– Jointer

– 14″ Band Saw

– and a few other odds and ends.

For the drawers, I was thinking of assembling them using the “secret mitre dovetail”, but I’m thinking that may be too advanced for me. So… as a fallback, I’m thinking of simply using Mortise & Tenon for the complete drawer assembly. I am definitely making the drawer bottoms thinner and grooving them into the surrounds.

For the curved end, I do realized that the curve meets the back and front at an angle… But I do not believe that the angle is harsh enough to worry about. It simply means having to make an angled cut on the front and back where the curve meets them. No biggie.

When you say “I’ve set the curve back an 1/8″ from the top”, I’m not quite sure what you mean here. Again, I didn’t get the complete project returned so I was unable to follow your description. The idea sounds enticing, I simply would like to see what it looks like in the 3D view.

With respect to the assembly method, I am thinking of going with the biscuit option and the pocket hole joinery.

In any case, if you could get the complete project back to me, then I can provide further comments.

Thanks again, Ness!

Christopher

October 4, 2012

Hi Christopher,

I was just looking through your project.

Big thanks to Mark, for his excellent advice as usual.

I would have a few questions and comments :

I have reworked your project a bit and made the following tweaks:

For the doors and drawers:

– I’ve grooved all panels into the frames to a depth of 1/2″ this is probably better than 1/4″.

I’m not sure how you are thinking of making the frames and panels.

The panels are 1/2″ but you could make them thinner.

– I’ve set up a assembly library to make the door frames from 3″ and the drawers from 2″ wide timber.

– How are you thinking of assembling the door and drawer frames, mortise+tenon, dowels, false tenons?

to advise you on this could you tell me what equipment and facilities you have?

– I’ve added slack to the doors and drawers using a library method.

On general assembly:

– I’ve tweaked a bit the boards so that they are easier to assembly

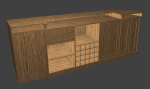

– I’ve rearranged the framed back panel so that the intermediate uprights separate each frame. This will work better for assembly and maintain the rhythm of the back as you already have the side of the left cabinet separating the door from the others.

On drawers:

– How are thinking of assembling the drawers?

– I adjusted the sides to over pass the counter frontage but this depends on the type of assembly you’ll be using.

– You might consider making the drawer bottoms thinner and grooving them into the surrounds.

On the curved end:

– How are you thinking of making the curved section?

– Curve meets the straight sections at an angle, it might be better to adjust so that the last sections of the curves meet the left side and the front at right angles.

On the top:

– I’ve set the curve back an 1/8″ from the top, this will make it easier to build and give a moulded effect when assembled.

Just and idea.

Globally the project is looking good but we’ll now have to decide on the hard ware and assembly method.

I attach the Polyboard file and a couple of images :

All the best,

Ness

Hi Mark!

I understand where you are going with the added uprights in the plinth area (which is why I do not understand why PolyBoard limits the plinths to only the fronts and backs). I could always add them, separate from the plans.

The ventilation slots, I have moved forward by 1/4″. Somehow, I thought I had placed them far enough ahead, but thank you for noticing that I hadn’t.

I will look into the exact thickness of the Oak Plywood, here in Canada, when it comes time to purchase. If there is any deviation, I will set the application to metric and make the appropriate adjustments.

Yes, it is my intent to have over-passing rails on the doors, drawer facades, and back panels. When it came to assembling them in PolyBoard, I only had two options… All rails being the same size or the top being one size and the rest another. I opted for the latter and decided to go with 3″ wide boards on top and 2″ boards on the sides and bottom. I’m hoping this will look good. If not, I will make adjustment to have the 3″ board on the bottom as well.

For the slack in the double-door and the double-drawer, I gave it 1/4″. I cannot seem to figure it out for the single doors though…

As to the overlap you’re suggesting to the stile and rails of the doors and rear panels, I added a 1/2″ to the height and 1/2″ to the width in the oversizing parameter of the center panel for the doors and drawers, and I’ve added a 1/4″ overlap to the crossbars and uprights of the panels. Will that do the trick?

Again, Mark, I really appreciate your help on this! I’ve attached the updated files…

Christopher

Hi Christopher.

All looks good.

Now these are just observations and wont detract from your plan as it is..

We would have made the plinths as either one complete section like the top section so that we did not have to extend the base of each unit out as the foot rest. It would make assembly easier, but use more materials and make the whole project heavier, so no real gain.

I would however add uprights (front to back) in the plinth area for additional strength.

I would bring the ventilaltion slots slightly forward by 6mm (1/4″) to give a little play with the backs.

Keep an eye on the material (Is ply in Canada 19mm…. I would think its 18mm (3.4″) which will make a slight adjustment on the cutlist when its done…..) In the UK standard MDF / PLY is 18mm with a veneered board being 19mm (1mm for the veneers).

Are you intent on the overpassing rails on the doors and back panels. Just my ‘two pennarth’ but overpassing stiles looks better.

Make the lower rail slightly wider to give a better feel to the doors.

As always, put a bit of slack in the door width and height, say 2mm on each edge because you dont want to be planing them back after. If you are going to use ‘blum’ or ‘european’ hinges as I think they may be called in Canada, you will deninately need the slacks added.

Add a 10mm overlap to the door stiles and rails in the edit section of the doors otherwise when you cut the centre panel it will fall through the middle…..

Cant spot anything else at present…. Great job…

Mark

Woohoo!! I figured out my problem with the drawers! I wasn’t clicking on the “Assemble” button when I was creating them…

Attached is the updated Home Bar Project 6.0 and modified Center Bar Section.

My question to you guys now is, “would there be anything that you would do differently with respect to how the fittings are setup?”

Thanks!

Christopher

1 Guest(s)