We’re no longer living in the age of the pencil and paper, but using CAD software to design your furniture is still inefficient and time-consuming. You’re drawing all your designs manually, the only difference is that it’s on a computer.

Lots of industries have already automated these manual processes and use 3D design software, so why is the woodwork industry lagging behind? It’s time to modernise.

Using Wood Designer’s Polyboard 3D design software can cut costs for your furniture design business.

1. Take less time to learn and design

CAD software is complicated to learn and complex to use. When you’re running a small furniture design business, you simply don’t have the time to learn a new program, the resources to dedicate to training a specialist, or the budget to hire a CAD technician.

Our Polyboard 3D software is intuitive and easy to learn and use, with no steep learning curve, so you can start designing furniture in minutes.

It’s parametric software so it means you can quickly input dimensions, and you can do all the designs yourself with no need to pay to outsource this function.

2. Streamline the process of winning customers

If you’re using CAD software, it’s simply too time-consuming to show potential customers 3D designs while you are trying to win their business. You want to know you’ve already won the business before you create the design.

In contrast, Polyboard is so quick that you can output a 3D visual and send it to the client at the same time as the quote for business. This helps the customer visualise what you have in mind, and it means they are more likely to be happy with the finished product (with no surprises).

With Polyboard, you can also input the costs of materials and hardware, and add in labour costs as a percentage of materials. You can then output an error-free quote immediately.

3. Assemble furniture quicker and more accurately

If you use CAD software, it’s easy to get the dimensions wrong, but difficult to change them even if you notice an error, which can slow down the assembly process.

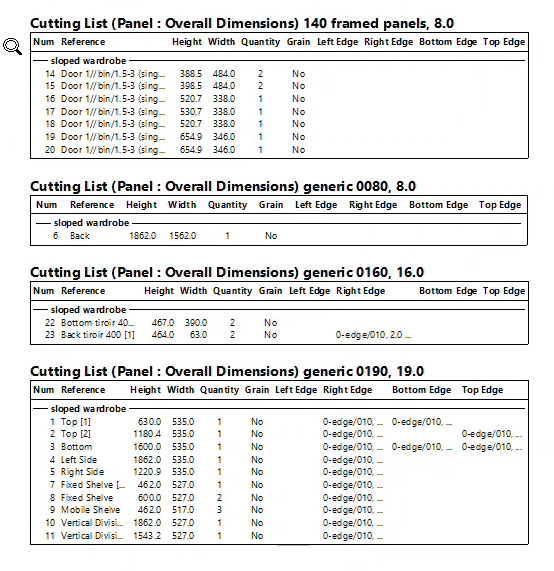

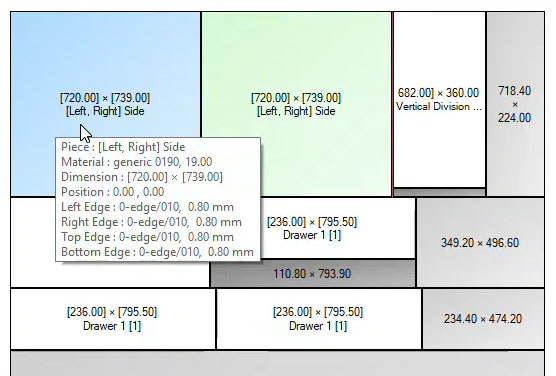

With Polyboard, you can easily change the dimensions if you spot a mistake, so you don’t have to waste time redesigning the furniture until you get it right. All outputs are updated automatically in the cut list and CNC plans.

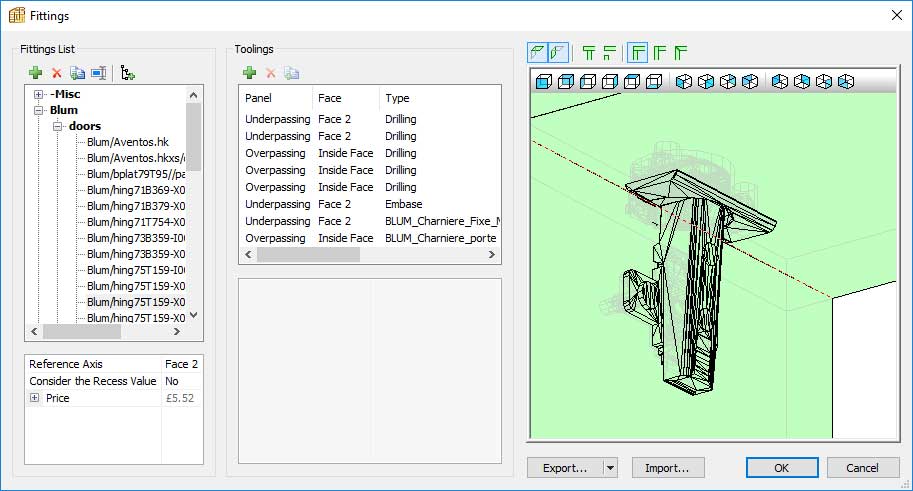

If you use a CNC machine, you can speed up assembly even more by having all the parts and machinings ready to assemble.

4. Speed up the manufacturing process

Time is money. If you use CAD software then, even if you are designing the same (or similar) furniture, you have to start the process from scratch each time.

If you use Polyboard, you can set your preferences once in the software’s style sheets – specs such as hardware, edging, drawer setup, joints, etc – and then apply this, again and again, each time you design that type of furniture. You can even have multiple different style sheets for different types of furniture.

While Polyboard has models you can use for the design of your furniture, you can also create a model library for your bespoke products. Then all you have to do is open a model, resize it, apply your style sheets, and output the result.

In fact, one of our customers has reduced design and production time by 50% to 60% by using Polyboard for furniture design.

By saving this time, you can also bring your focus back to building furniture, spending more time with your existing customers, and trying to win new customers, rather than having to spend ages on manual design.

5. Make changes easily

Your customer has new ideas for the design of their furniture or they want to change the dimensions. If you’re using CAD software, you have to redraw each part manually.

As Polyboard is parametric software, to make these changes, all you need to do is enter the new overall dimensions and everything resizes automatically. The output is instantaneous as well.

You can input the new parts requirements into our OptiCut software (which integrates with Polyboard) and the solution then optimises how you cut parts out to minimise material waste You can reduce costs as there are no production errors when cutting parts.

But don’t just take our word for it; we’ll leave that honour to Sean Murphy, one of our very happy customers:

Polyboard is the best piece of software we have ever had. No more mistakes in the workshop!

Click here to find out more about the benefits of Polyboard.