Cutting Optimisation

Cutting list optimizer for professional workshops

Looking for an alternative to manually calculating your cutting list? We’ll take a look at how to transition from manual cut list production to a design and manufacturing process that automates creation…

Perfect grain and more: major OptiCut update

OptiCut 6 is now available and features a range of powerful new capabilities you’ve asked us for to cut your parts even more effectively. To help you access these new features we’ve…

Technological developments in the woodwork trades

From wooden axes to CNC machining in over 4000 years of history Analysis of the history and evolution of information technology in the woodworking trades The definition of a trade In this…

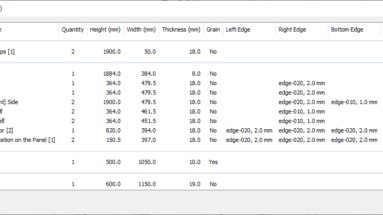

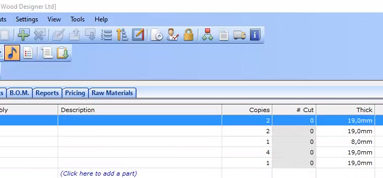

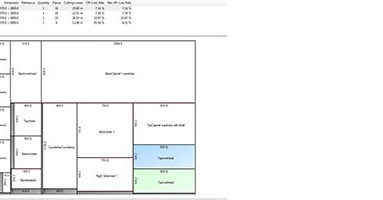

CutList Plus and Polyboard Integration

CutList Plus is a cutting optimisation solution that will take a cutting list and from it generate a cutting diagram or map optimised to minimise material waste. Polyboard is our furniture design…

Changing Units and Currency in OptiCut

Changing the units in OptiCut is quick and easy. Click on Tools > Units You can change the units for the Length, Surface and Angle. You cannot change the currency in OptiCut….

OptiCut Label Printing

Print off labels to reference and identify your parts, and adjust your printing settings to your requirements. OptiCut will let you print a label for each part that you can stick on…

Bar Materials Optimization in OptiCut (Extended)

A more detailed explanation of bar optimization set up, including adding user defined profiles from CAD software and angle cut integration. If you are a wood worker manufacturing parts of fixed length…

Optimising Bar Materials in Opticut

OptiCut can just as easily optimize bars as panels, and determine the most efficient cutting maps for complex cut angles. Here’s how. OptiCut is a great piece of software for optimizing sheet…