Some additional settings to allow you to fine tune your optimization depending on your priorities, whether that be waste, cutting time or processing time.

In our last videos we showed how to set up OptiCut to optimize a cutting list. In this video we’ll show you how to adjust your setting for the best possible optimization.

You can adjust your settings to fine tune your optimization and to give priority to specific variables like cut time, total costs or minimum materials.

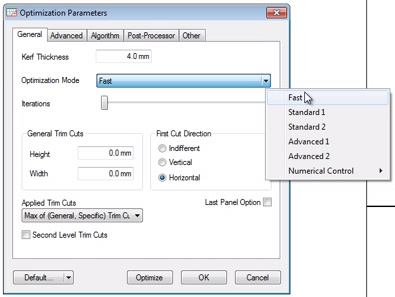

Let’s take a look at some of the more common settings by clicking on the Optimization Parameters icon.

Here you have the possiblity of setting up your Saw Kerf Thickness which defaults to 4mm. We suggest you cut a piece of material and measure the actual saw kerf that applies in your workshop.

There are several different Optimization Modes to choose from:

Fast

Standard 1

Standard 2

Advanced 1

Advanced 2

Numercial Control

The faster OptiCut processes the optimization, the less optimized the waste will be. The more advanced the optimization, the slower it will be.

You can also define a trim cut which entails cutting your initial panels along the edge to remove any damage so you can start off with a perfectly clean edge for your actual parts.

You can also define First Cut Direction:

Indifferent means OptiCut decides the best way to start. But depending on your machine and set up, you may need to set the first cut as vertical or horizontal.

Let’s see what happens when we optimize using the Fast Mode. In this case, the optimization took 0.07 seconds and optimized onto 3 sheets.

The waste or unrecoverable off cut rate was 5.05%.

Now let’s optimize using the Advanced 2 Mode. This took longer, at 9.63 seconds, but we optimized onto 2 panels with waste down to 4.15%.

Now click on the Advanced Parameters tab.

Here you can determine additional priorities to optimize with (slide to the right for increased importance), so by:

Off cut quality

This will result in bigger off cuts but we might need more panels to do it

Cutting lines and Cutting Linear or lengths

These will impact on your total cutting time.

Turnarounds (only available in Advanced Modes)

This impacts on how often you need to turn your panels around. The more you do this, the longer it will take, although you will waste less.

You’ll need to experiment yourself and determine what you own priorities are.

There are a number of additional parameters which we aren’t going to cover today. Initially stick with General and Advanced parameters which will give you very good results.

You can download OptiCut here.