We’d like to introduce Peter Brown, a furniture builder from Australia. He has very kindly explained how he works with our woodworking design software Polyboard and OptiCut, for cutting optimisation. In particular he discusses how he recently put together a beautiful side board piece in Jarrah, a timber only found in the area where he lives.

***

Hello my name is Peter Brown from Perth, Western Australia.

I have been in the furniture industry for 51 years, all of my working life. Having always worked for myself, including 30 years being part owner of a large commercial furniture company.

In late 2012 I came across Polyboard one night while playing on the net. I purchased Version 5 which was still being developed so I learnt as the product was developed. I then purchased OptiCut to complete the package.

I quickly developed my skills to produce working drawings with optimized cutting lists and great 3D designs to present to my clients.

These days I still love working in my workshop. I live on 6 acres and my workshop is situated towards the back of the block. I have all the machines for producing all types of furniture and solid timber products including a small CNC that I use for drilling panels and machining various shapes.

Recently I had clients approach me to design and manufacture a 4 metre Jarrah (local hardwood timber only found in the south west of Western Australia) side board and to incorporate lead light panels to the upper doors & design a kitchen renovation.

They loved the design and commissioned me to produce the unit. I hand selected the Jarrah crown cut veneers and solid timber for the carcass and had them layed up on 16mm MDF. They were then cut and edged with a 2mm solid Jarrah edge strip.

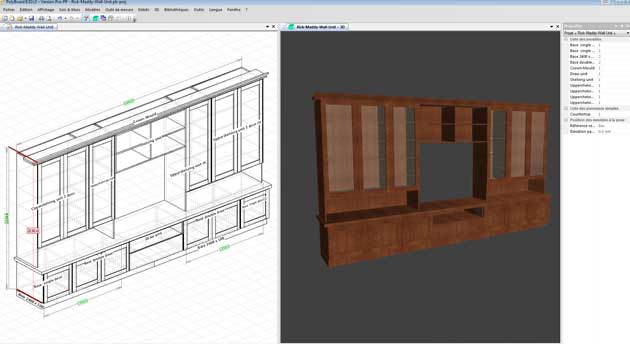

Here is the project set up in Polyboard:

The lower doors are 12mm Jarrah MDF inner panel with 60 x 25mm timber frame. The upper doors are 60 x 25mm rebated to suit the lead light panels, all joined with Domino floating tenons.

The top is solid Jarrah manufactured from 150 x 50 solid timbers joined with Epoxy resin. I finished the timber works in 30% satin polyurethane.

The kitchen was finished in Vinyl wrapped facings with engineered stone bench tops and waterfall end. All Blum hardware was used on this project.

This was all designed in Polyboard, Ness supplied a short video I asked for to show how to use partial views (very helpful).

I still like to have a hands on approach to my furniture making, I cut all my parts on my panel saw and edge them on my hot melt edgebander.

Polyboard works great for me as once I have completed my designs I can produce an order for all my Vinyl wrapped components at a touch of a button before I start my manufacturing, thus saving valuable time.

The client was very pleased with the finished works.

Cheers, Peter Brown

***

A big thank you to Peter for taking the time to explain how he uses our woodworking design software. Polyboard and OptiCut integrate really well together to create a complete design and manufacturing package. If you’d like to know more about the software, please let us know. We can also arrange an online demonstration for you.

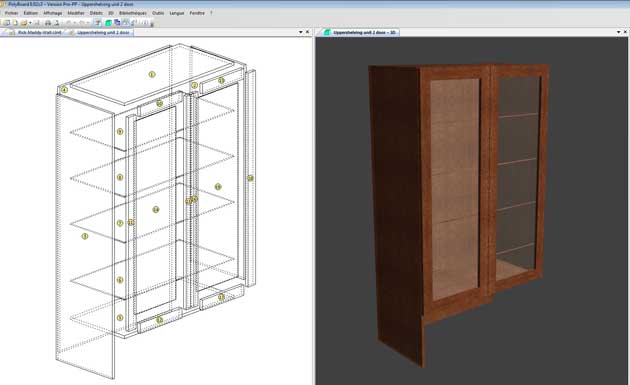

Here’s a link to the Polyboard partial views video for reference. It’s a nice feature to enhance the presentation of your projects and to aid assembly.

Finally, here are two more really nice projects Peter built using Polyboard, plus links to their forum threads.

American oak hutch

American oak sideboard