Mach3 and Mach4 are PC based software solutions for generating the GCode to run your CNC machine. They are developed and supported by ArtSoft.

Mach3 came first and targeted the hobby market.

Mach4 comes in different levels, for the hobbyist again, up to the larger professsional workshop running their CNC day in, day out.

LazyCam is CAM software developed by ArtSoft itself and comes free with Mach3. It allows import of DXF and other files formats into Mach3, which in turn generates the code to run a CNC.

LazyCam is no longer being developed by ArtSoft however. It was never completely finished and in any case was used with Mach3 which isn’t really intended for professional use as we mentioned above.

If you are a professional using ArtSoft software, Mach4 is a much better option. But you’ll need CAM software to go with it.

There are a huge range of options to choose from including ArtCam, CamBam, VCarve Pro or Aspire and Alphacam.

We often get asked what CAM software we recommend for use with Polyboard, our furniture design and manufacturing software. For 3 axis CNCs, we tend to recommend VCarve Pro. For more complex 4 and 5 axis CNCs, you may need to look at a higher end CAM software like Alphacam or Enroute or DDX’s EasyWOOD.

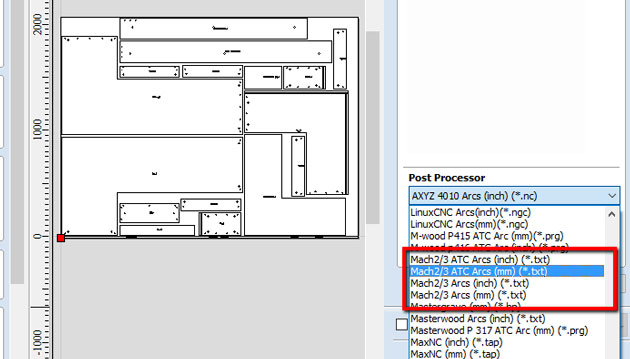

Let’s take a look at VCarve Pro. First of all, the very good news…it comes with a Mach post processor so the integration will work in full. Please check with Vetric who make VCarve to determine which post processor will be the best one for your CNC.

It’s also inexpensive and works very well. It offers a basic nesting solution too for nesting CNCs.

Aspire is an upgrade on VCarve Pro, also made by Vetric. It works just as well and offers in addition conversion of 2D drawings into 3D models with relief work. A great addition but not absolutely necessary for cabinetry and other furniture manufacture.

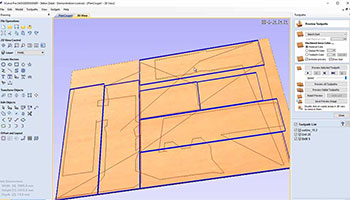

To explain in brief the integration, first design a furniture project in Polyboard which creates a cut list of the project. Then output part by part DXF files of this cut list from Polyboard into VCarve.

VCarve then outputs the machine code to run the Mach configured CNC. The whole process only take a few minutes and massively cuts down on human error as it is virtually automatic.

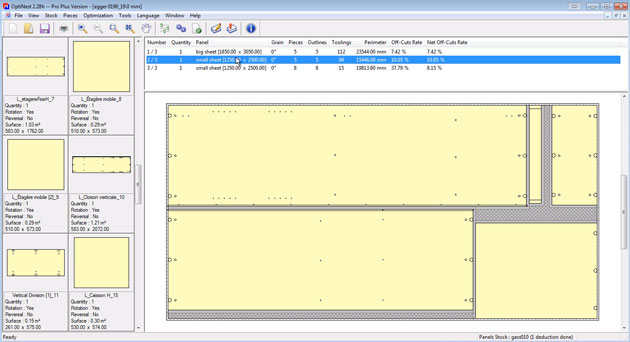

For a complete nesting solution, add our OptiNest nesting optimisation package to the set up for labelling of parts and stock and off cut management (not provided by VCarve). Polyboard exports the project cut list to OptiNest which produces a DXF file of the nesting map for each panel.

This is a very fast and accurate way to get from design to production, much faster than manually inputting the dimensions of each part into your CAM software. It works for furniture manufacture but also stair manufacture using our StairDesigner software.

Please get in touch if you would like to discuss the best set up for you.