Furniture Design

4 Ways to Build Better Cabinet Projects

Whether you’re building a kitchen, fitted shelving, wardrobes or another custom cabinet project, your individual units are only a part of the design process. To accommodate typical build and assembly issues and…

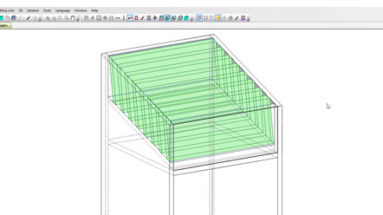

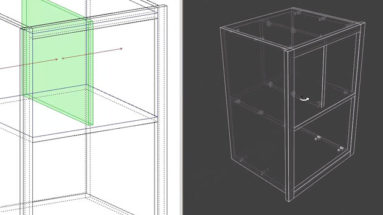

How to create a display cabinet in PolyBoard

In response to a query on the forum, we’ve made a video to show you how to design a display cabinet in PolyBoard, the type you might use for marketing materials like…

The new way to add face frames, fillers, plinths and more using Polyboard

The latest version of Polyboard includes a new design element called External Zones which brings even more design flexibility to your projects. They allow you to add spaces (or volumes) outside your…

Getting lost in the wilds: Vitap CNC integration, Polyboard training and more

We were recently asked to give a 3 day Polyboard training and CNC set up session to the company Grosjean Concept Bois, in the east of France in the Haut Doubs region…

Polyboard 7 full version revealed plus download advice

We’re excited to announce the official release of the Polyboard 7 full version, now available for download and sale. This major update to Polyboard version 7 is packed full of new features,…

5 ways 3D design software can cut costs for your furniture business

We’re no longer living in the age of the pencil and paper, but using CAD software to design your furniture is still inefficient and time-consuming. You’re drawing all your designs manually, the…

Christmas woodwork videos, and a great marketing idea for 2019

A very Merry Christmas to all of you who celebrate the festivities. If you don’t, we hope you’ve got some time off and wish you a peaceful and happy time with friends…

How to build online sales for your workshop

We’re just incredibly busy! …that was the first thing Mark told me when I rang him recently to discuss the latest news on Polyboard. Mark is the owner of Mark Nichol’s &…